Audi Q5: Tools and Equipment

Testing Equipment, Tools and Materials

General Information

Note

Note

This list outlines the testers, tools and materials required for expert refrigerant circuit repair work.

- For tools and materials available from the distribution center or importer. Refer to → Chapter "Tools and Materials Available from Distribution Center or Importer".

- For commercially available tools and materials. Refer to → Chapter "Commercially Available Tools and Materials".

- For improvised tools. Refer to → Chapter "Improvised Tools".

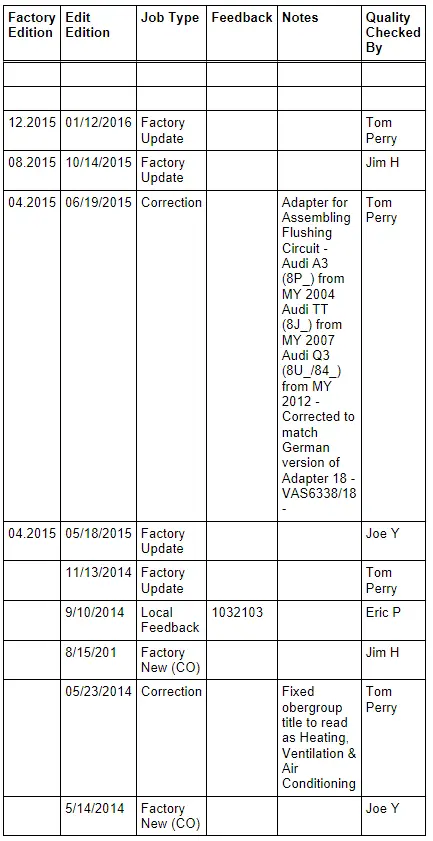

Tools and Materials Available from Distribution Center or Importer

Commercially Available Tools and Materials

Improvised Tools

Tools and Materials Available from Distribution Center or Importer

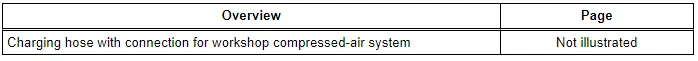

Service station/A/C Service Station (this illustration shows ), currently available A/C service stations. Refer to the Parts Catalog (Tools; Special Tools and Equipment: A/C and Heating).

- Work procedures: The operations "testing, extraction (recycling), evacuation and charging" are to be performed in line with the relevant operating instructions.

- The filters and dryers installed are to be replaced at the latest at the end of the period of use specified in the operating instructions and whenever the station has been drained (keep replacement filter to hand. Available from equipment manufacturer. Refer to A/C service station operating instructions.

- Use can also be made of service stations not described here. Refer to the Parts Catalog (Tools; Special Tools and Equipment: A/C and Heating).

- Currently available A/C service stations are equipped with a program for flushing the refrigerant circuit; the flushing equipment required for flushing is also included in delivery of these A/C Service Stations. Refer to the Parts Catalog (Tools; Special Tools and Equipment: A/C and Heating).

Note

Note

- This A/C service station has the following known units: charging cylinder, pressure gauge set, vacuum pump, shutoff valves and charging hoses.

- One quick-release coupling each (for service connections on high and low-pressure side) is included in the scope of delivery of this service station.

- Current vacuum display (LED) appears after pressing the "Evacuate" button again.

Leak detection unit, currently available leak detection units. Refer to the Parts Catalog (Tools; Special Tools and Equipment: A/C and Heating).

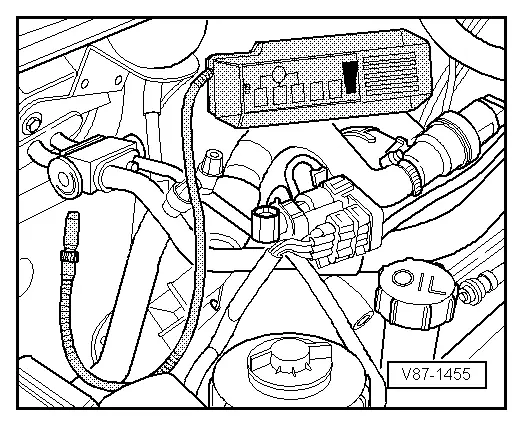

Leak detection system (for example Leak Detection Kit -VAS6201A-, currently available leak detection systems. Refer to the Parts Catalog (Tools; Special Tools and Equipment: A/C and Heating).

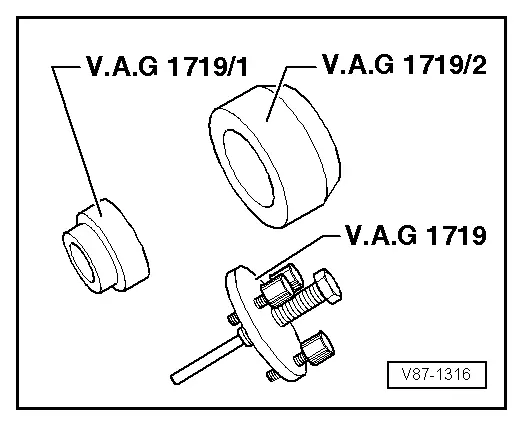

Puller for A/C Clutch Set -VAG1719- (for "Zexel" A/C compressor)

A/C Adapter Set -VAG1785-

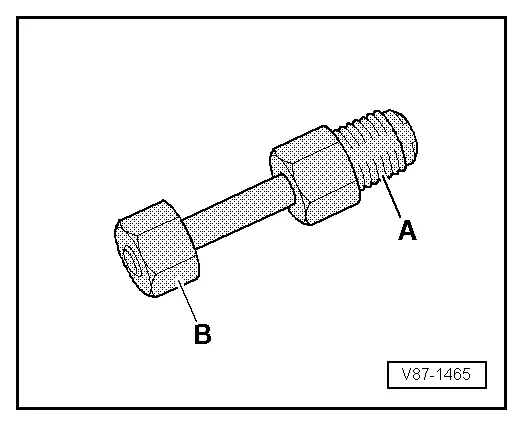

Adapter for cleaning refrigerant circuit (flush with refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blow through with compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen".)

A - 5/8"-18 UNF thread for conical seal

B - Union nut (for connection with O-ring) with thread

- A/C Adapter Set - M18 x 1.5 -VAG1785/1-

- A/C Adapter Set - M20 x 1.5 -VAG1785/2-

- A/C Adapter Set - M24 x 1.5 -VAG1785/3-

- A/C Adapter Set - M28 x 1.5 -VAG1785/4-

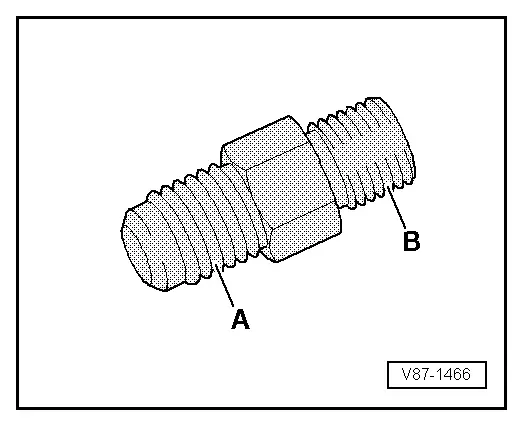

Adapter

A - 5/8"-18 UNF thread for conical seal

B - Threaded connection for O-ring

- A/C Adapter Set - M18 x 1.5 -VAG1785/5-

- A/C Adapter Set - M20 x 1.5 -VAG1785/6-

- A/C Adapter Set - M24 x 1.5 -VAG1785/7-

- A/C Adapter Set - M28 x 1.5 -VAG1785/8-

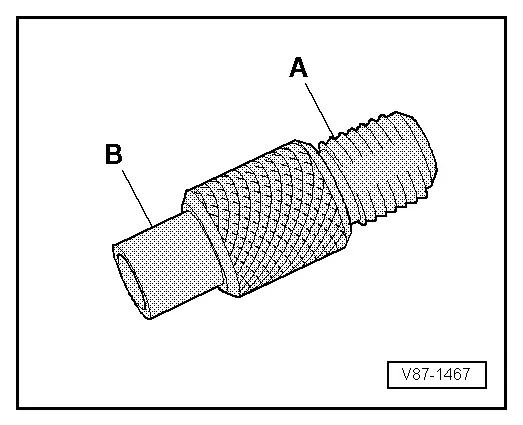

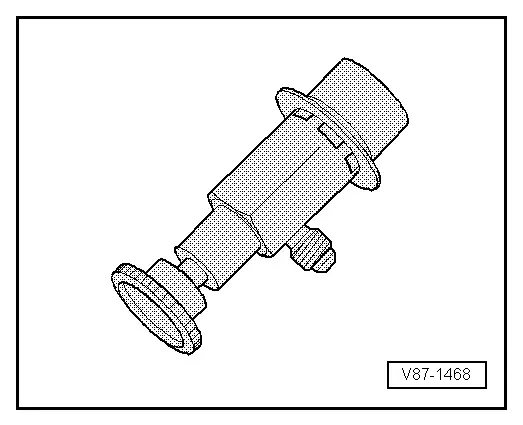

Valve adapter

A - 5/8"-18 UNF thread for conical seal

B - Internal thread with valve opener

- M10 x 1.25 VAG1785/9 (for connections with valve on high-pressure side)

- M10 x 1.5 VAG1785/10 (for connections with valve on high-pressure side)

Note

Note

- A Schrader valve is screwed into connection -A-.

- A valve opener must be installed in the charging hose connection.

- Various adapters from adapter set are also part of the Refrigerant Circuits Adapter Set 1 -VAS6338/1-.

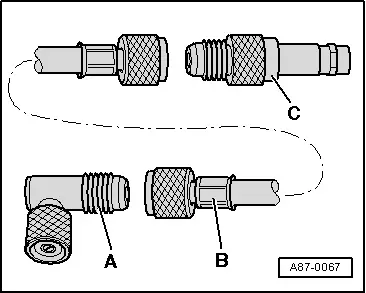

A/C Adapter Set -VAG1786-

A - A/C Adapter Set - Adapter 1 -VAG1786/1- (only for connections with small valve insert on low-pressure side)

B - Charging hose with union nut 5/8"-18 UNF (short version)

C - A/C Adapter Set - Adapter 2 -VAG1786/2-.

Note

Note

- For connections with large valve insert (standard on "Zexel/Valeo" compressors, gradual change to small valve insert from 10/1994), use is to be made of adapter VAG1785/10 (remove valve from adapter VAG1785/10 or install valve opener in charging hose -B-).

- Beginning from production year 2006, the name of the "Zexel" A/C compressor was changed from "Zexel" to "Valeo".

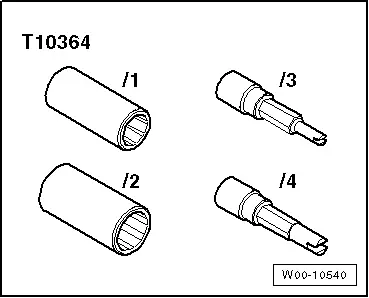

Refrigerant Sockets -T10364-

Note

Note

For removing and installing service connections and valve units when the refrigerant circuit is empty.

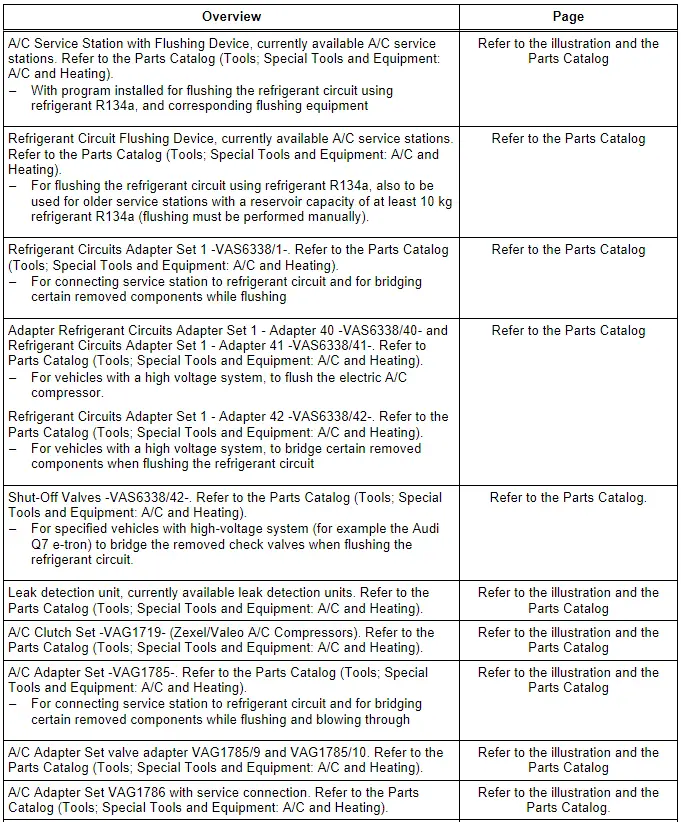

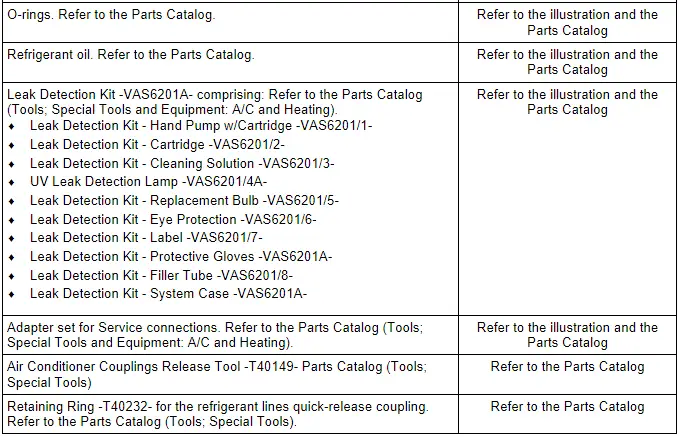

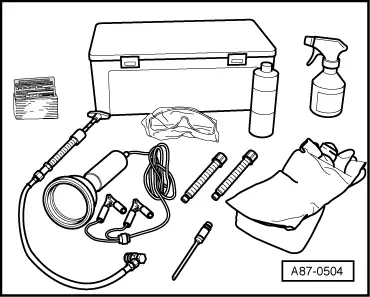

Commercially Available Tools and Materials

Fin comb

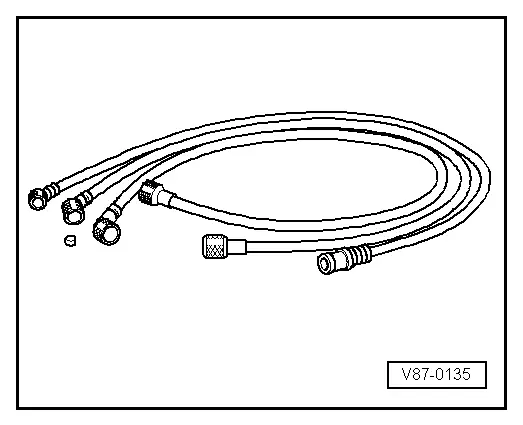

Fill hoses

5/8"-18 UNF thread

Note

Note

- Use differently colored charging hoses (1800 mm long).

- Have valve opener and spare seals to hand.

- A charging hose in short version is also included in Refrigerant Circuits Adapter Set 1 -VAS6338/1-.

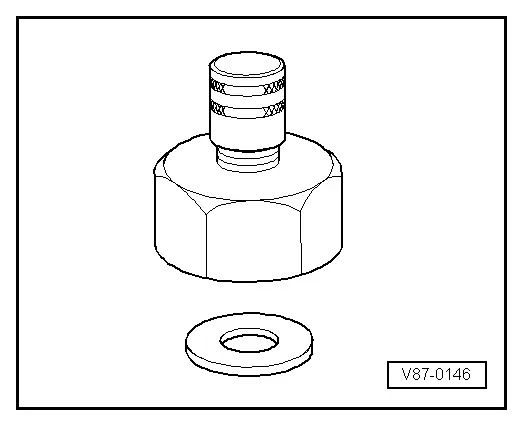

Connection piece for refrigerant cylinder with seal, quick-release coupling connection or threaded connection 5/8" - 18 UNF

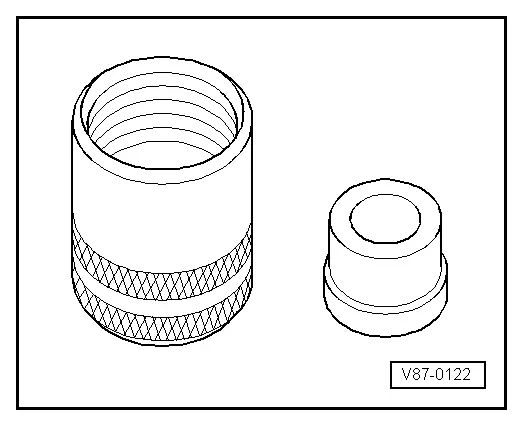

Valve caps with spare seals (for 5/8"-18 UNF thread)

Seals can also be used for charging hoses.

Note

Note

Valve caps with spare seals are also included in Refrigerant Circuits Adapter Set 1 -VAS6338/1-.

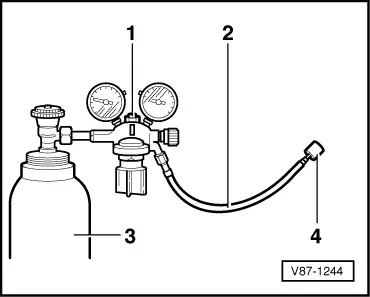

Pressure gauge set with pressure reducer for nitrogen (max. reducing pressure: 15 bar (218 psi) )

1 - Pressure gauge set

2 - Pressure hose (inner diameter 5 mm, length 2 m)

3 - Nitrogen

4 - Hose fitting

Note

Note

For connection to A/C Adapter Set -VAG1785- with 5/8"-18 UNF thread

Quick-release coupling adapter for service connections

- High-pressure side, nominal size 16 mm

- Low-pressure side, nominal size 13 mm

- 2x release tool (Sharan)

Note

Note

This quick-release coupling is delivered with the service station.

Improvised Tools

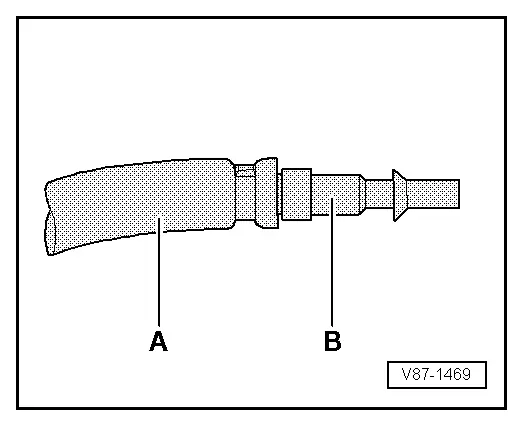

Charging hose with connection for workshop compressed-air system

A - Charging hose 5/8" - 18 UNF** (version with large inner diameter)

B - Connection for workshop compressed-air system ** (always use filter)

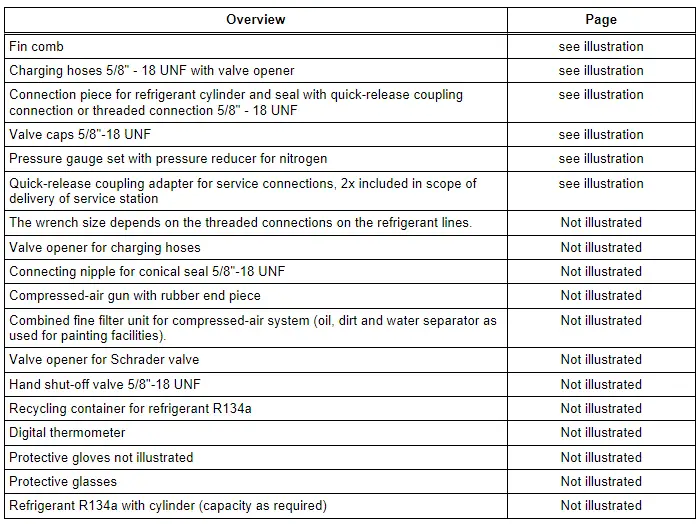

Revision History

DRUCK NUMBER: A0053300221