Audi Q5: Adaptive Cruise Control (ACC), Calibrating

Adaptive Cruise Control (ACC), Calibrating, Calibration Procedure with Setting Device Basic Set -VAS6430/1-

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Vehicle Diagnosis System - Updated Cable - 3m -VAS5051/5A-

- Setting Device Basic Set -VAS6430/1-

- Wheel Alignment Computer

- ACC Adjuster -VAS6190/2-

Note

Note

- The Setting Device Basic Set -VAS6430/1- may have to be adapted for the adjustment procedure. Refer to → Chapter "Setting Device Basic Set -VAS6430/1- Converting for the Adjustment Procedure".

- Before driving the vehicle onto the alignment stand, check whether there is a sufficiently large space between the vehicle and the Setting Device Basic Set -VAS6430/1A-. The distance between the Setting Device Basic Set -VAS6430/1- and the vehicle must be 120 cm +- 5 cm.

- If there is not enough space, drive vehicle the backward on the alignment stand in order to be able to use the space.

- Before beginning the adjustment, check the DTC memory and correct any malfunctions present.

The adjustment procedure is described here using the Setting Device Basic Set -VAS6430/1A-. The ADC Adjustment Fixture -VAS6041- and the ADC Adjustment Fixture -VAS6041/1A- can also be used.

Note

Note

If there was a previous axle alignment, the steps under "Calibration procedure without a previous axle alignment" should not performed.

Calibration procedure without a previous axle alignment

- Connect the battery charger. Refer to → Electrical Equipment; Rep. Gr.27; Battery; Battery, Charging.

- Select the ACC calibration button on the alignment computer.

- Install quick clamps on the rear wheels.

- Install measuring sensors on the rear wheels.

- Perform a rim run-out compensation on the rear wheels.

Note

Note

The Setting Device Basic Set -VAS6430/1- must not be moved on the calibration beam.

Calibration procedure with or without a previous axle alignment

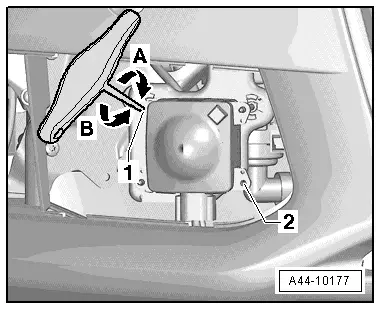

- Release the bracket -1- and remove the air intake grille -2-.

- Remove all dirt on the sensor lens.

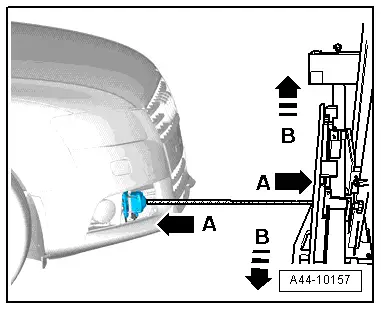

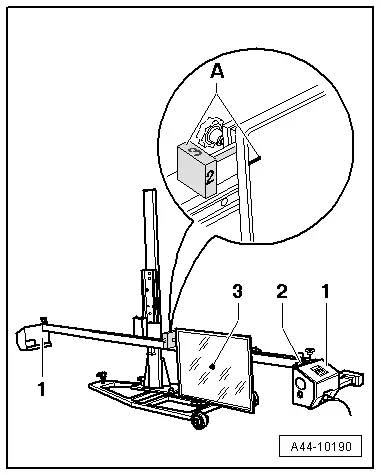

- Position the Setting Device Basic Set -VAS6430/1- at a distance -A- of 120 cm +- 5 cm from sensor lens to mirror surface.

WARNING

WARNING

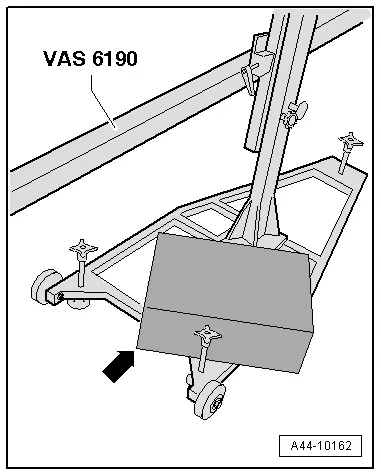

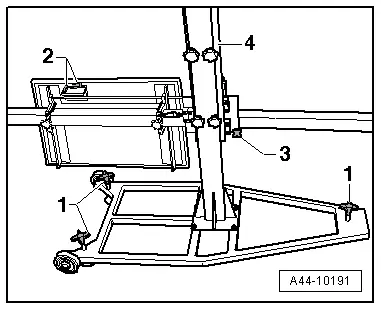

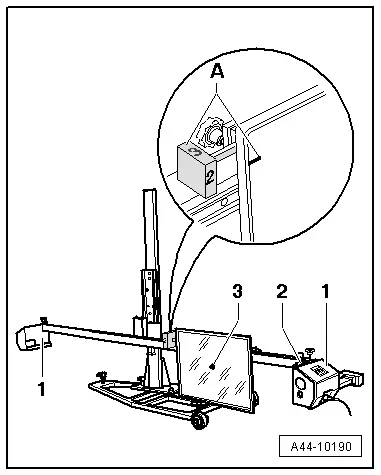

- Place a toolbox or container weighing approximately 5 to 7 kg on the Setting Device Basic Set -VAS6430/1- before installing the measuring sensors and moving the mirror on the calibration beam.

- If weight is not put on the Setting Device Basic Set -VAS6430/1-, the Setting Device Basic Set -VAS6430/1- could tip over when the mirror is moved and/or when the measuring sensors are installed.

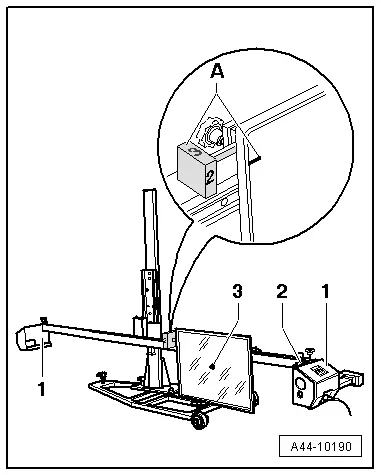

- Load the Setting Device Basic Set -VAS6430/1- with the weight -arrow- as shown in the illustration.

- Mount the front wheel measuring sensors -1- onto the Setting Device Basic Set -VAS6430/1-.

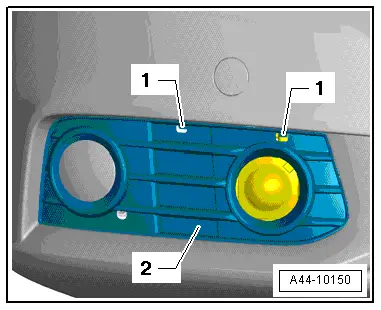

- In area -A-, bring item -2- on rotary knob into alignment with marking on mirror (number 2 on rotary knob must face toward vehicle).

- Now align the Setting Device Basic Set -VAS6430/1- by sliding it sideways -arrows B- so that the laser beam is horizontally centered on the senor lens.

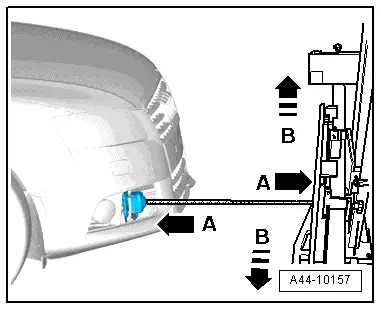

- Bring the bubble levels -2- on the Setting Device Basic Set -VAS6430/1- into balance using adjustment screws -1-.

- Adjust vertical slits -4- on Setting Device Basic Set -VAS6430/1- so that laser beam is centered vertically on sensor lens.

- Adjust the same front axle individual toe settings using fine adjustment screw -3-.

- The difference between individual toe values must be less than 6' or they must be the same.

- Bring bubbles -2- on measurement sensor -1- into balance.

- Now using the laser beam -3- on the Setting Device Basic Set -VAS6430/1-, check if the laser beam contacts the sensor lens.

Note

Note

- If the laser beam still meets the sensor lens at this step after adjusting the same individual toe values, the Setting Device Basic Set -VAS6430/1A- is aligned correctly (positioned).

- If the laser beam does not meet the sensor lens, the Setting Device Basic Set -VAS6430/1A- must be aligned again.

- Connect the Vehicle Diagnostic Tester:

- Connect the connector of the Vehicle Diagnosis System - Updated Cable - 3m -VAS5051/5A- to the diagnostic connection.

- Switch on the Vehicle Diagnostic Tester.

The Vehicle Diagnostic Tester is ready to operate when it displays operating modes in button fields.

- Switch the ignition on.

- Touch Guided Fault Finding.

- Select in succession:

- Brand

- Type

- Model year

- Version

- Engine Codes

- Confirm data entered.

Wait until the Vehicle Diagnostic Tester has check all the control modules in the vehicle.

- Press the Go to button and select "Function/component selection".

- Select the corresponding program in "Guided Functions".

Now follow instructions on screen to perform adjustment.

- Turn the ACC Adjuster -VAS6190/2- in direction of -arrow A or B- and use the lower screw -2- and the upper screw -1- for precision adjustment in "Guided Fault Finding".

WARNING

WARNING

The ACC adjustment is confirmed when "output diagnostic test complete" appears in the -Vehicle Diagnostic Tester-.

- Switch off the ignition.

- Disconnect the connector of the Vehicle Diagnosis System - Updated Cable - 3m -VAS5051/5A- from the diagnostic connection.

- Disconnect the battery charger. Refer to → Electrical Equipment; Rep. Gr.27; Battery, Charging.

- Install the air intake grille. Refer to → Body Exterior; Rep. Gr.63; Front Bumper.