Audi Q5: Subframe, Servicing, Rear Bonded Rubber Bushing for Rear Final Drive, AWD Vehicles

Special tools and workshop equipment required

- Subframe Bushing Tool Kit -3301-

- Bearing Installer - Control Arm -3346-

- Subframe Bushing Assembly Tool -T40185-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

Removing

- Remove the rear final drive. Refer to → Rep. Gr.39; Final Drive.

- Loosen the nuts on both rear muffler brackets but only as far as to where the thread begins.

- Place the Engine and Gearbox Jack -VAS6931- with Universal Transmission Support -VAG1359/2- under the subframe.

- Place a piece of wood under the subframe.

- Remove the rear subframe bolts.

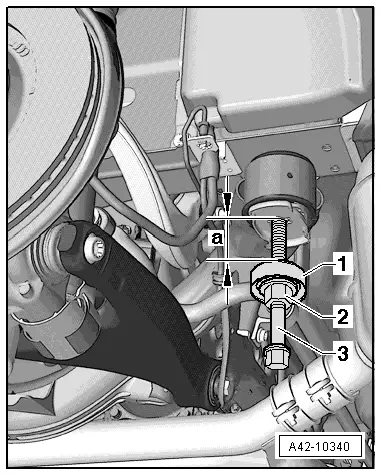

- Install the Bearing Installer - Component -3346/2- with the Subframe Bushing Tool Kit -3301- and Nut - Component -3346/3- approximately 1.5 cm into the vehicle body as illustrated.

1 - Subframe Bushing Tool Kit -3301-

2 - Nut - Component -3346/3-

3 - Bearing Installer - Component -3346/2-

Note

Note

Turn the Nut - Component -3346/3- on the Bearing Installer - Component -3346/2- until dimension -a- 4 cm is reached.

- Lower the subframe just 4 cm.

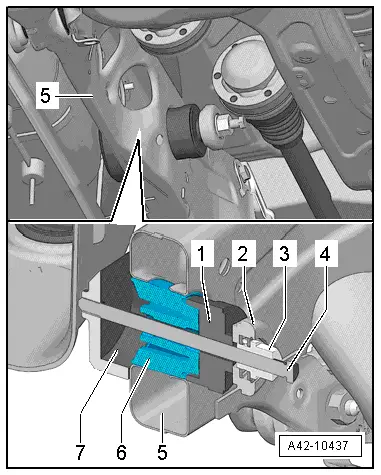

- Attach the tools to the subframe as illustrated.

1 - Subframe Bushing Assembly Tool - Tube -T40185/1-. Side "A" must face the subframe.

2 - Subframe Bushing Tool Kit -3301-

3 - Bearing Installer - Control Arm - Nut -3346/3-

4 - Spindle -T40185/9-

5 - Subframe

6 - Bonded Rubber Bushing

7 - Rear Differential Assembly Tool - Pipe -T40185/7-. The "open" side faces up.

- Remove the bearing from the subframe while turning at the Control Arm Bearing Installer - Nut -3346/3- and counter-holding at the Rear Differential Assembly Tool - Spindle -T40185/9-.

Installing

Install in reverse order of removal. Note the following:

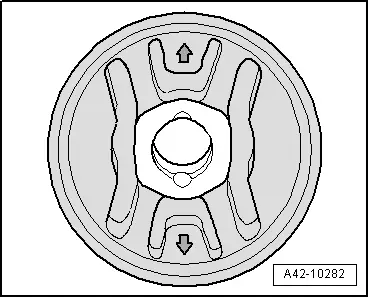

- Note the installation position for the rubber bonded bushing.

- The arrows on the back of the rubber bonded bushing must point up or down.

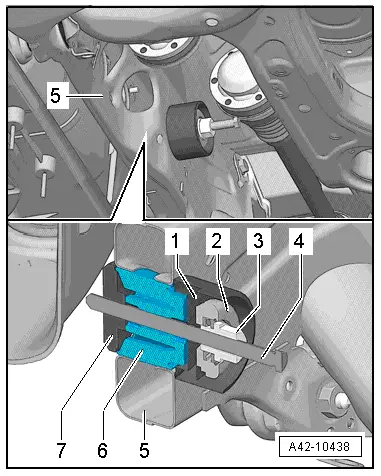

- Attach the tools and the bonded rubber bushing to the subframe as illustrated.

1 - Subframe Bushing Assembly Tool - Tube -T40185/2-. Side "A" must face the subframe.

2 - Subframe Bushing Tool Kit -3301-

3 - Bearing Installer - Control Arm - Nut -3346/3-

4 - Spindle -T40185/9-

5 - Subframe

6 - Bonded Rubber Bushing

7 - Rear Differential Assembly Tool - Thrust Plate -T40185/8-

- Install the bearing all the way into the subframe while turning at the Nut - Component - 3346/3- and counter-holding at the Spindle -T40185/9-.

Note

Note

If paint damage has occurred during bearing replacement, repair using corrosion protection, primer and black top coat.