Audi Q5: Lower Transverse Link, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

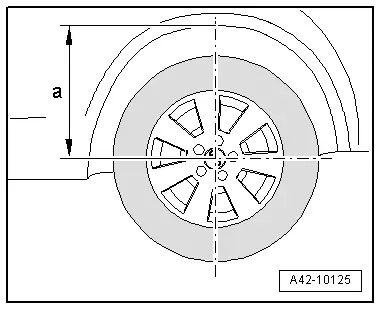

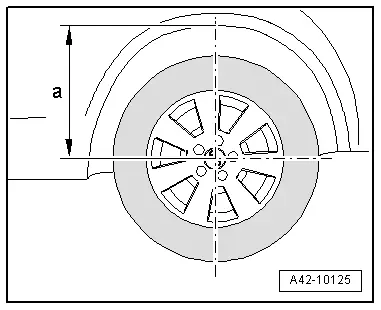

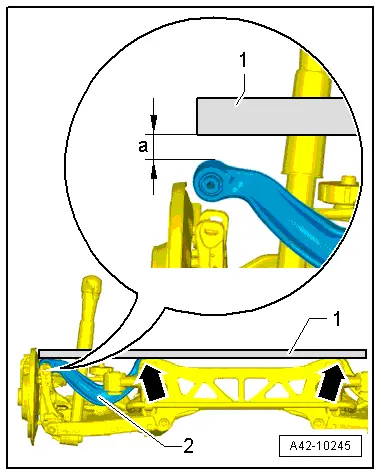

- Determine dimension -a- from the center of the wheel to the lower edge of the wheel housing before starting work while the vehicle is resting on its wheels.

- Place the vehicle on a hoist.

- Remove the wheel.

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

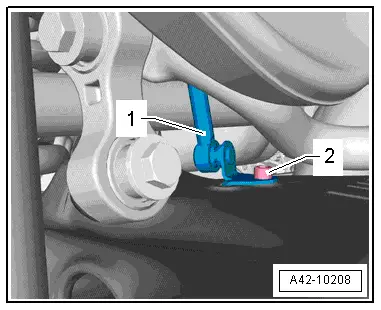

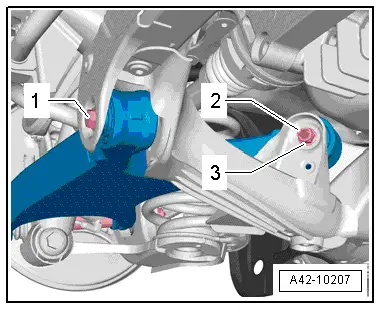

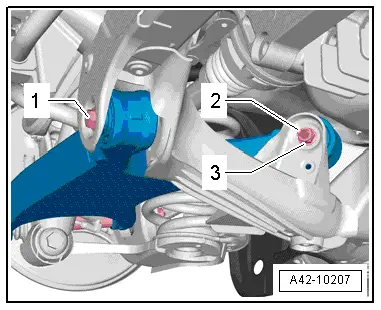

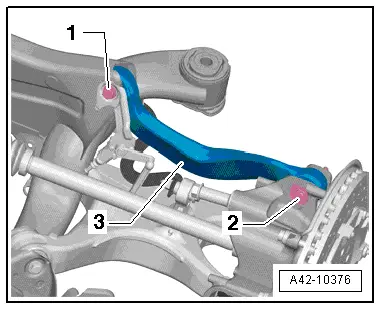

- On vehicles with a level control system sensor -1-, remove the bolt -2-.

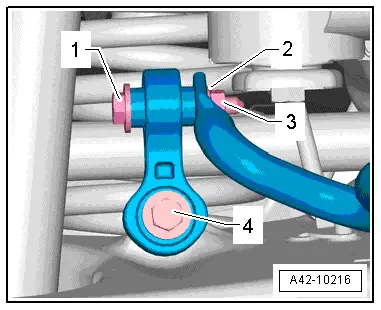

- Remove the bolt -4-.

- Remove the nut -3-.

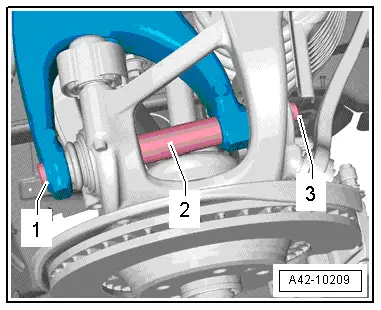

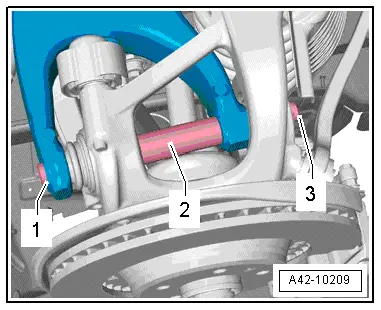

- Remove the bolt -1- and the spacer tube -2-.

Note

Note

Axle alignment is necessary if the nut -3- is loosened or the bolt -1- is removed.

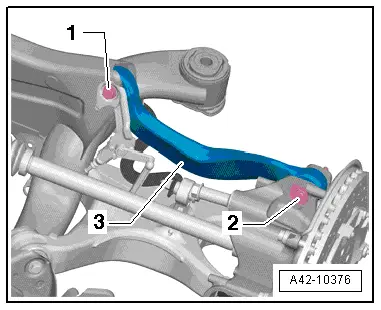

- Remove the bolt -1-.

- Remove the nut -3- and bolt -2-.

- Remove lower transverse link.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension screws when vehicle is in curb weight or control position.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

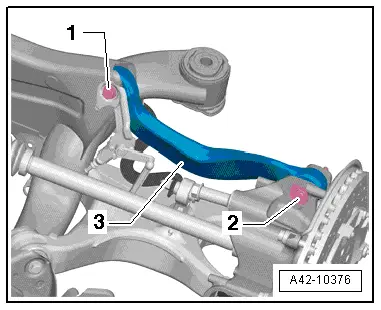

- Insert the lower control arm and install the bolt -1- loosely.

Note

Note

To make sure there is enough clearance to tighten the bolt -2-, the aerodynamic trim panel and the wheel spoiler must be removed. Refer to → Body Exterior; Rep. Gr.66; Underbody Panel.

- Install the bolt -2- and install the nut -3- loosely.

- Insert the bolt -1- with the spacer tube -2- and install the nut -3- loosely.

Caution

Caution

Do not tighten the threaded connection using the nut -3-.

- Tighten the bolt -1-.

- Tighten the rest of the threaded connections.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Tighten the wheel. Refer to → Chapter "Wheel Bolt Tightening Specifications".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with automatic head lamp range control, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamps; Headlamp, Adjusting.

- If the Level Control System Sensor was removed and installed on a vehicle with electronically controlled damping or if the linkage was loosened, the control position must be reprogrammed using the Vehicle Diagnostic Tester. Refer to → Chapter "Control Position, Programming".

- If the control position was reprogrammed on vehicles with lane assist, the Directional Stabilization Assistance Control Module -J759- must be calibrated again. Refer to → Chapter "Lane Assist, Calibrating".

Upper Transverse Link, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Note

Note

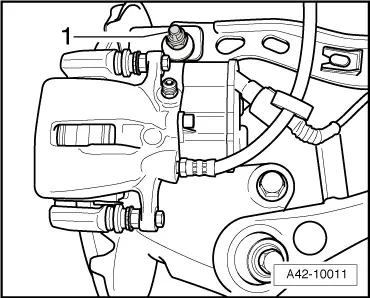

Due to the inaccessibility of the inner threaded connection -1-, the upper control arm can only be removed when the subframe has been removed.

Removing

- Determine dimension -a- from the center of the wheel to the lower edge of the wheel housing before starting work while the vehicle is resting on its wheels.

- Place the vehicle on a hoist.

- Remove the wheels.

- Remove the subframe. Refer to → Chapter "Rear Axle, Removing and Installing".

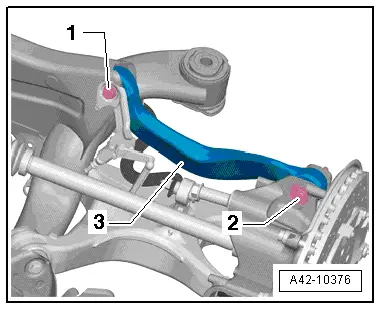

- Mark the position of the eccentric bolt -2- the wheel bearing housing, for example using a felt-tip pen.

- Separate connections -1- and -2-.

- Remove upper transverse link -3-.

Installing

Note

Note

Replace the bolts and the self-locking nuts.

Installation position of the upper transverse link on the subframe

- Install the upper control arm -3- on the threaded connection -1- by hand.

- Lay a ruler or straight edge -1- flat against the upper control arm -arrows-.

- Position the upper control arm -2- so dimension a = 8 mm +- 1 mm between the straight edge -1- and the stamping burr on the upper control arm -2-.

- Tighten the upper control arm -3- on the subframe in this position.

- Screw wheel bearing housing on control arm and tighten new nut to 20 Nm. Note the installation position of the centering washer -2-.

- Install the subframe. Refer to → Chapter "Rear Axle, Removing and Installing".

- Loosen the threaded connection -1-.

- Lift the wheel bearing hub into curb weight position and tighten the threaded connection -1-. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Tighten the wheel. Refer to → Chapter "Wheel Bolt Tightening Specifications".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".