Audi Q5: Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

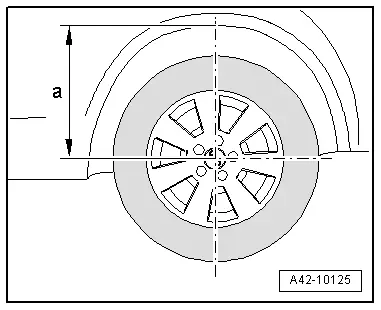

- Before starting work, determine dimension -a- from the center of the wheel to the lower edge of the wheel housing while the vehicle is resting on its wheels.

- Place the vehicle on a hoist.

- Remove the wheels.

Caution

Caution

Do not damage the paint on the stabilizer bar when removing and installing.

- Depending on the engine version, remove the rear muffler from the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

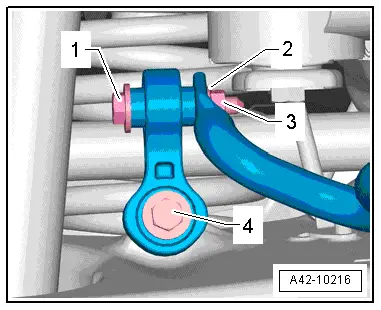

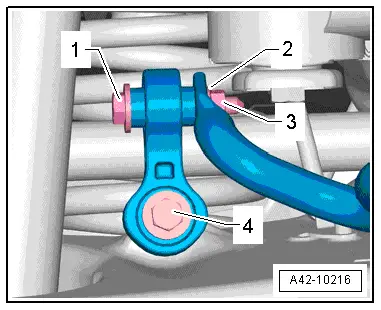

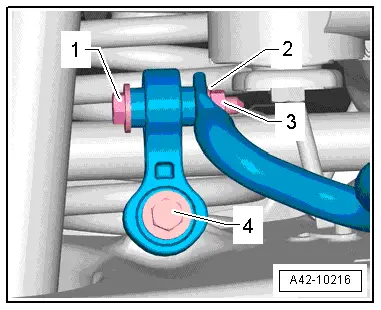

- Remove the right and left bolt -4-.

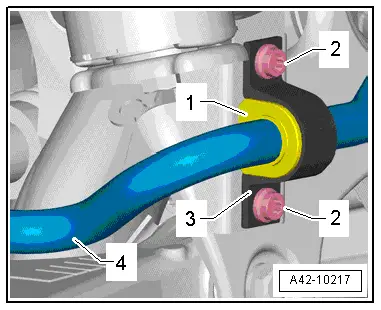

The stabilizer bar -4- is completely removed and installed with the rubber bushings -1- and clamps -3-. Do not remove the clamps and rubber bushings.

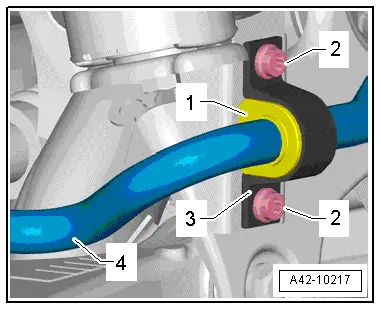

- Remove the left and right bolts -2- and the stabilizer bar -4- and coupling rods.

- Detach the coupling rod from the stabilizer bar and remove it.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension screws when vehicle is in curb weight or control position.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Attach the coupling rod to the stabilizer bar and tighten the threaded connection hand tight.

- Insert the stabilizer bar and tighten the right and left bolts -4- so that they are still loose.

- Install the left and right bolts -2- so that they are still loose.

- Then tighten the left and right bolts -2- evenly.

- Tighten the left and right bolt -1- and nut -3-.

- Tighten the left and right bolts -4-.

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- Tighten the wheel. Refer to → Chapter "Wheel Bolt Tightening Specifications".