Audi Q5: Subframe, Servicing, Bonded Rubber Bushing and Hydraulic Bonded Rubber Bushing for Subframe

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931- with Universal Support Plate -VAG1359/2-

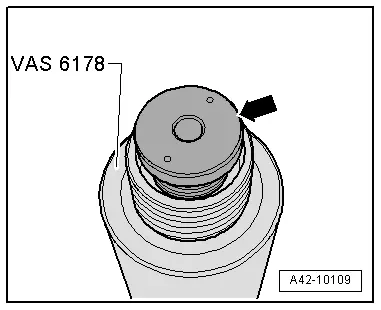

- Hydraulic Press -VAS6178-

- Pneumatic/Hydraulic Foot Pump -VAS6179-

- Bearing Installer - Wheel Hub/Bearing Kit -T10205-

- Hydraulic Press - Rear Subframe Bushing Tool Kit -T10263-

- Rear Bushing Tool -T40033-

- Subframe Bushing Assembly Tool -T40185-

- Bearing Installer - Control Arm -3346-

- Subframe Bushing Tool Kit -3301-

Note

Note

- If a bonded rubber bushing is faulty, then the bonded rubber bushing on the opposite side must also be replaced. Refer to the Parts Catalog for the allocation.

- Check the other bushings before replacing a faulty bonded rubber bushing.

- If cracks, oil leaks or other damage is visible, this bonded rubber bushing must also be replaced.

- Two different front bonded rubber bushings were installed during production, a conventional bushing and a hydraulic bushing. Allocation. Refer to the Parts Catalog.

- Place the vehicle on a hoist.

- Remove the wheels.

- Remove the coil springs. Refer to → Chapter "Spring, Removing and Installing".

Note

Note

- In order to replace the rubber bonded bushing, the subframe must be lowered either at the front or at the rear. It is not necessary to remove the subframe.

- Lower the subframe alternating between the front and rear. This avoid having to perform an axle alignment.

- Do not lower the subframe more than 4 cm.

- Identify mounting location to subframe before removing the bonded rubber bushing.

Replace the front bonded rubber bushing or the front hydraulic bonded rubber bushing.

Applies to all

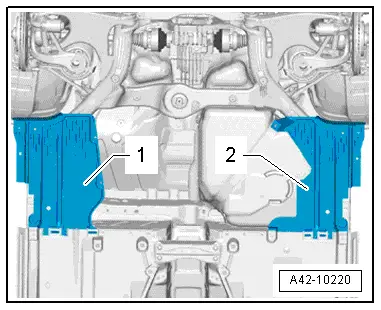

- Remove the covers -1- and -2-. Refer to → Body Exterior; Rep. Gr.66; Underbody Panel.

- Remove the wheel spoiler. Refer to → Body Exterior; Rep. Gr.66; Underbody Panel.

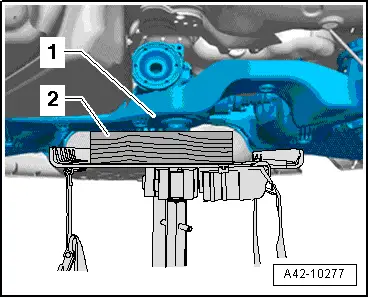

- Place Engine and Gearbox Jack -VAS6931- with Universal Transmission Support -VAG1359/2--1- under the subframe.

- Place a wood block -2- under the subframe -1-.

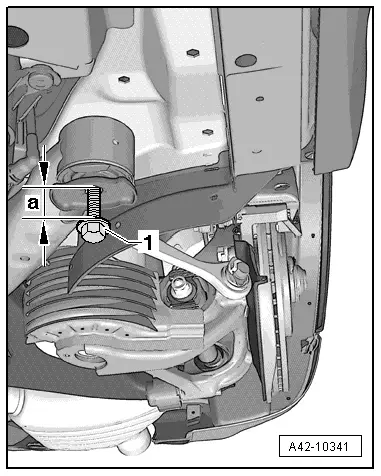

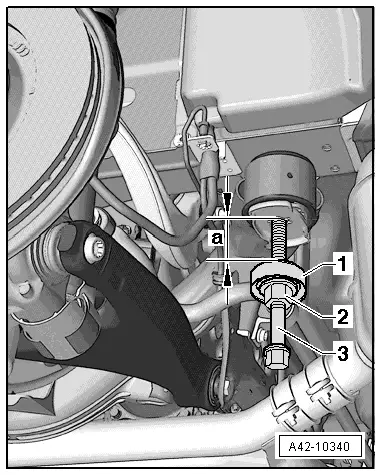

- Remove the left and right bolt -1-.

- Install the removed bolt -1- into the body on the opposite of the bonded rubber bushing to be removed as illustrated.

Note

Note

Install screw -1- only until dimension -a- 4 cm is reached.

- Lower the subframe 4 cm only.

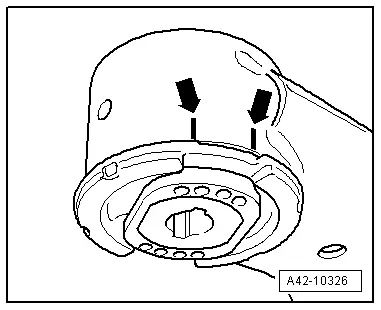

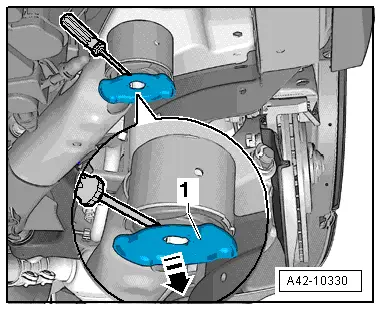

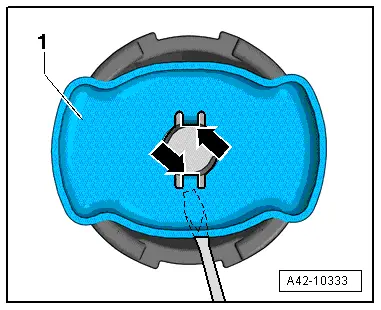

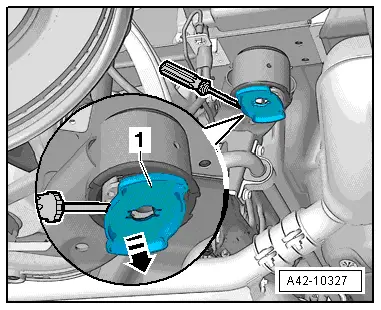

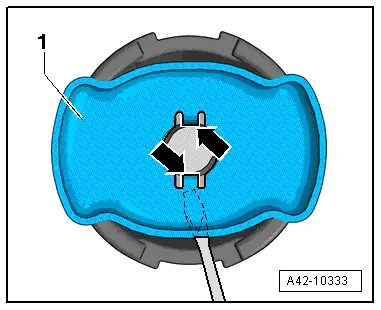

- Carefully pry anti-twist mechanism -1- off the bonded rubber bushing with a screwdriver near the retaining tab. Do this in several steps alternating from side to side.

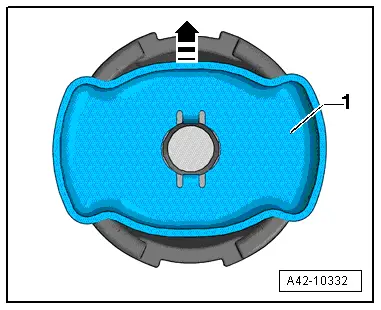

Applies to a hydraulic bonded rubber bushing

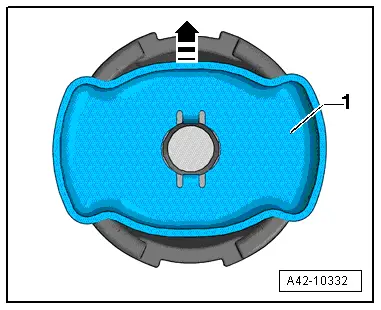

- Remove the plastic insert -1- upward as illustrated.

Applies to all

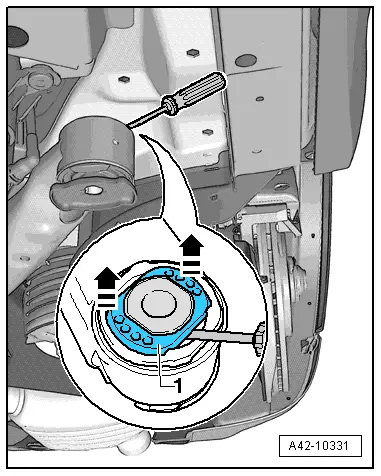

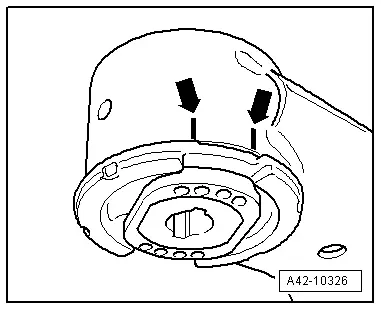

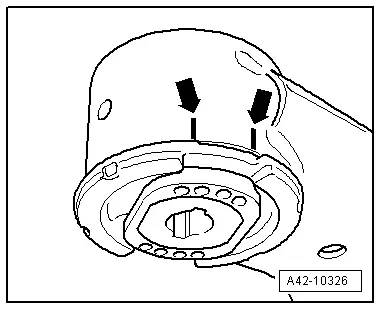

- Mark the installation position of the bonded rubber bushing or the hydraulic bonded rubber bushing on the subframe -arrows-.

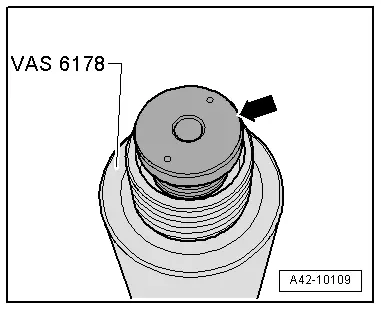

- If necessary, the support -arrow- with the "small" interior diameter must be removed from the Hydraulic Press -VAS6178- and the Pressure Head -T10205/13- for it must be installed.

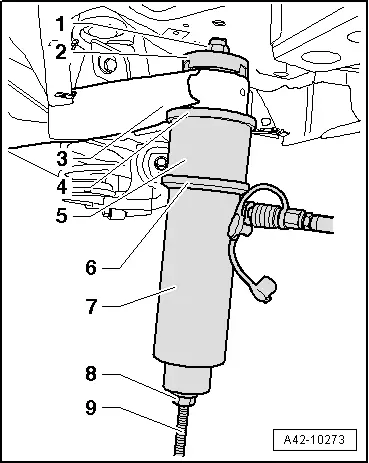

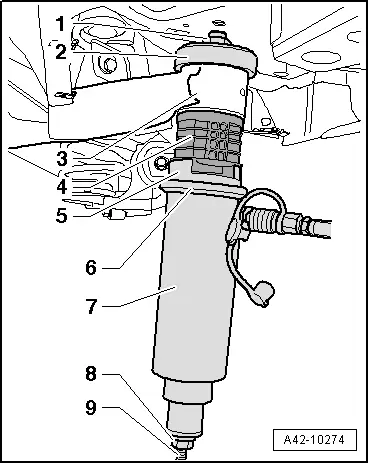

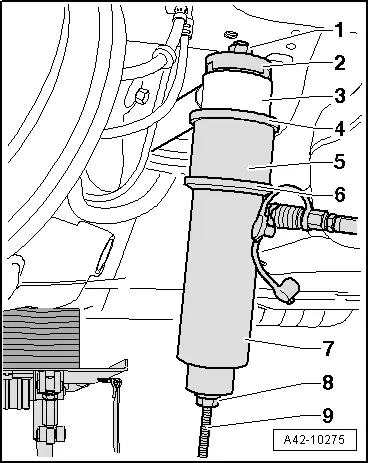

- Place the tools on the front bonded rubber bushing as shown in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool - Thrust Piece -T40185/5-. The opening faces the rubber bonded bushing.

3 - Subframe

4 - Subframe Bushing Assembly Tool - Support Ring -T40185/6-. The conical side must face upward and the ribs must fit into the openings in the rubber bonded bushing.

5 - Rear Bushing Tool - Tube -T40033/3-

6 - Bearing Installer - Wheel Hub/Bearing Kit - 4 -T10205/4-

7 - Hydraulic Press -VAS6178-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4- The spindle pins face downward.

WARNING

WARNING

- Hold the Hydraulic Press -VAS6178- firmly while pressing out.

- Bonded rubber bushing loosens "abruptly". There is the risk of injuries by tools and bonded rubber bushing coming off!

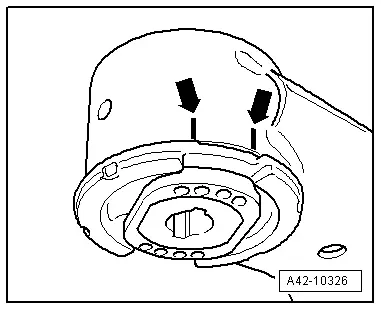

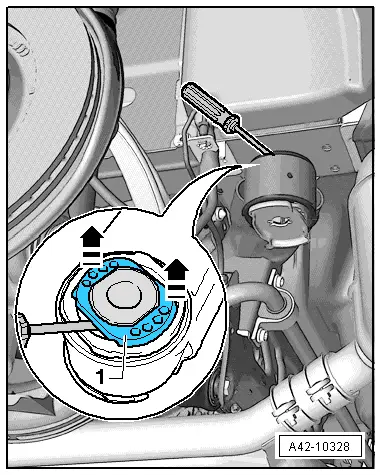

Installation position for front bonded rubber bushing

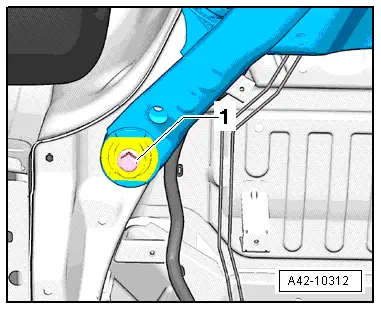

The anti-twist mechanism (aluminum) -1- is perpendicular to direction of travel. The -arrow- points in driving direction.

- Before installing the front bushing, carefully pry anti-twist mechanism -1- off the bushing with a screwdriver near the retaining tabs -arrows-. Do this in several steps alternating from side to side.

- Place the tools on the front bonded rubber bushing as shown in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Thrust Piece -T40185/4-

3 - Subframe

4 - Bonded rubber bushing or the hydraulic bonded rubber bushing

5 - Subframe Bushing Assembly Tool - Thrust Piece -T40185/3-

6 - Bearing Installer - Wheel Hub/Bearing Kit - 4 -T10205/4-

7 - Hydraulic Press -VAS6178-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4- The spindle pins face downward.

- Align the bonded rubber bushing with the markings made previously and push it in until the collar comes in contact with the bushing in the subframe "without any gaps". Tension and press over cylinder several times if necessary. While pulling in, make sure the bonded rubber bushing does not cant, otherwise outer ring could be damaged.

- The ends of the rubber bead on the bonded rubber bushing must align with the markings -arrows- on the subframe.

Note

Note

After replacing the bearing, fix any paint damage on the subframe with corrosion protection, primer and black top coat.

- Attach the anti-twist mechanism to the bushing.

Install in reverse order of removal.

Replace the rear hydraulic bonded rubber bushing.

- Loosen the nuts on both rear muffler brackets but only as far as to where the thread begins.

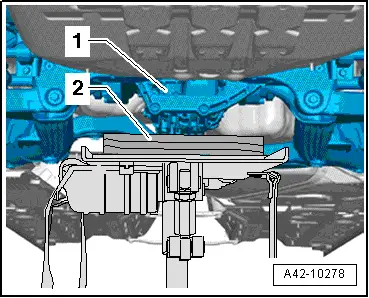

- Place Engine and Gearbox Jack -VAS6931- with Universal Transmission Support -VAG1359/2--1- under the subframe.

- Place a wood block -2- under the subframe -1-.

- Remove the rear subframe bolts -item 20-.

- Install the Bearing Installer - Component -3346/2- with the thrust bearing from the Subframe Bushing Tool Kit -3301- and Nut - Component -3346/3-, as illustrated, on the opposite side of the bonded rubber bushing being replaced approximately 1.5 cm into the vehicle body.

1 - Subframe Bushing Tool Kit -3301-

2 - Nut - Component -3346/3-

3 - Bearing Installer - Component -3346/2-

Note

Note

Turn the Nut - Component -3346/3- on the Bearing Installer - Component -3346/2- until dimension -a- 4 cm is reached.

- Lower the subframe 4 cm only.

- Carefully pry the anti-twist mechanism -1- off the hydraulic bonded rubber bushing with a screwdriver near the retaining tab. Do this in several steps alternating from side to side.

- Remove the plastic insert -1- upward as illustrated.

- Mark the installation position of the hydraulic bonded rubber bushing on the subframe -arrows-, e.g. with a felt-tip marker.

- If necessary, the support -arrow- with the "small" interior diameter must be removed from the Hydraulic Press -VAS6178- and the Pressure Head -T10205/13- for it must be installed.

- Place the tools on the rear hydraulic bonded rubber bushing as shown in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Subframe Bushing Assembly Tool - Thrust Piece -T40185/5-. The opening faces the rubber bonded bushing.

3 - Subframe

4 - Subframe Bushing Assembly Tool - Support Ring -T40185/6-. The conical side must face upward and the ribs must fit into the openings in the bushing.

5 - Rear Bushing Tool - Tube -T40033/3-

6 - Bearing Installer - Wheel Hub/Bearing Kit - 4 -T10205/4-

7 - Hydraulic Press -VAS6178-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4- The spindle pins face downward.

WARNING

WARNING

- Hold the Hydraulic Press -VAS6178- firmly while pressing out.

- The hydraulic bonded rubber bushing releases "abruptly". There is a risk of the injury from the tools and the hydraulic bonded rubber bushing falling down.

Installation position, rear hydraulic bonded rubber bushing

The anti-twist mechanism (aluminum) -1- is perpendicular to direction of travel. The -arrow- points in driving direction.

- Before installing the front hydraulic bonded rubber bushing, carefully pry the anti-twist mechanism -1- off the bushing with a screwdriver near the retaining tab -arrows-. Do this in several steps alternating from side to side.

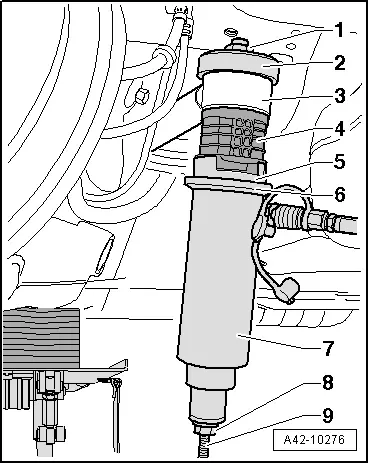

- Place the tools on the rear hydraulic bonded rubber bushing as shown in the illustration.

1 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

2 - Thrust Piece -T40185/4-

3 - Subframe

4 - hydraulic bonded rubber bushing

5 - Subframe Bushing Assembly Tool - Thrust Piece -T40185/3-

6 - Bearing Installer - Wheel Hub/Bearing Kit - 4 -T10205/4-

7 - Hydraulic Press -VAS6178-

8 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Nut -T10263/5-

9 - Hydraulic Press - Rear Subframe Bushing Tool Kit-Spindle -T10263/4- The spindle pins face downward.

- Align the hydraulic bonded rubber bushing with the markings and push it in until the collar comes in contact with the bushing in the subframe "without any gaps". Tension and press over cylinder several times if necessary. While pulling in, make sure the hydraulic bonded rubber bushing does not cant, otherwise outer ring could be damaged.

- The ends of the rubber bead on the bonded rubber bushing must align with the markings -arrows- on the subframe.

Note

Note

After replacing the bearing, fix any paint damage on the subframe with corrosion protection, primer and black top coat.

- Attach the anti-twist mechanism to the hydraulic bonded rubber bushing.

Install in reverse order of removal.