Audi Q5: Overview - Steering Gear

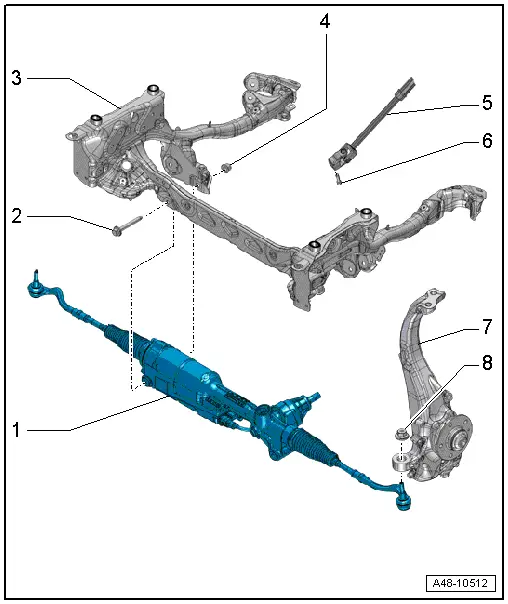

Overview - Steering Gear, Electromechanical Steering Gear

1 - Electromechanical Steering Gear with Tie Rods

- With Power Steering Control Module -J500-

- Removing and installing. Refer to → Chapter "Electromechanical Steering Gear, Steering Gear, Removing and Installing"

- Servicing. Refer to → Chapter "Steering Gear, Electromechanical Steering Gear, Servicing".

- There are different versions. Refer to the Parts Catalog.

A removable heat shield mat was installed on the steering gear at start of production. Be sure to install this mat if installing the old steering gear again.

A removable heat shield mat on the steering gear was replaced by a bonded heat shield mat as a running change. It is therefore not necessary to take the mat from the old steering gear and installing on a new steering gear.

A replacement steering gear comes with the bonded heat shield mat.

2 - Bolt

- 80 Nm +180º

- Always replace if removed

3 - Subframe

4 - Nut

- Pushed into the subframe

- Always replace if removed

5 - Steering Intermediate Shaft

6 - Bolt

- Tightening specification -item 4-

7 - Wheel Bearing Housing

8 - Nut

- 100 Nm

- Always replace if removed

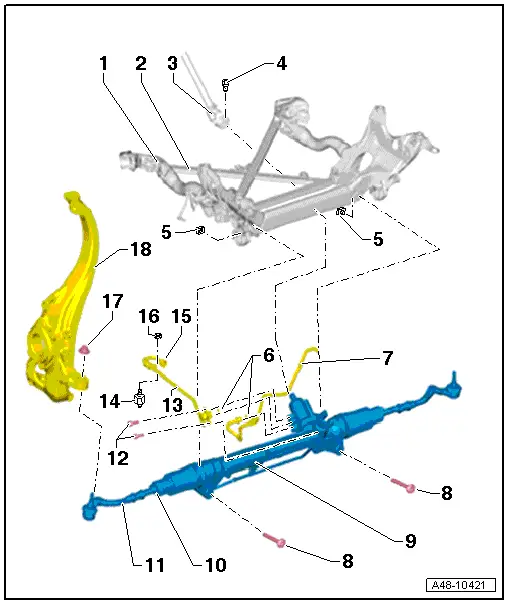

Overview - Steering Gear, Hydraulic Power Steering Gear

Power steering gear is completely removed and installed with tie rods.

1 - Subframe

2 - Crossbrace

3 - Steering Intermediate Shaft

4 - Bolt

- 30 Nm +90º

- Always replace if removed

- The threaded hole for the bolt must always be cleaned, for example, with a thread cutter

5 - Nut

- Always replace if removed

6 - Seal

- Always replace if removed

7 - Return Line

Caution

Caution

Insert the return line completely when installing.

- There are different versions. Refer to the Parts Catalog.

8 - Bolt

- 80 Nm +180º

- Always replace if removed

9 - Power Assisted Steering Gear with Tie Rods

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing, Hydraulic Power Steering Gear".

- Servicing. Refer to → Chapter "Steering Gear, Servicing, Hydraulic Power Steering Gear".

- Adjusting. Refer to → Chapter "Steering Gear, Adjusting".

- There are different versions. Refer to the Parts Catalog.

10 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing, Hydraulic Power Steering Gear"

11 - Tie Rod End

- There are different versions, with long or short thread on the joint pin; allocation. Refer to the Parts Catalog.

WARNING

WARNING

When replacing, make sure the length of the thread on the tie rod end is sufficient (there must be approximately 5 mm extra thread). If this is not the case, then install a tie rod end with a longer thread pin, allocation Parts Catalog.

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing, Hydraulic Power Steering Gear"

12 - Bolt

- 20 Nm

13 - Pressure Line

- There are different versions, with and without a separating point. Refer to the Parts Catalog.

Caution

Caution

Insert the pressure line completely when installing.

- There are different versions. Refer to the Parts Catalog.

14 - Rubber Bushing

- 6 Nm

15 - Union Nut

- 40 Nm

- A pressure line with a separating point does not have a union nut.

16 - Nut

- 6 Nm

17 - Nut

- There are different versions. Refer to the Parts Catalog for the allocation.

- Pay attention to the different nut versions and to the tightening specifications.

- Always replace if removed

18 - Wheel Bearing Housing

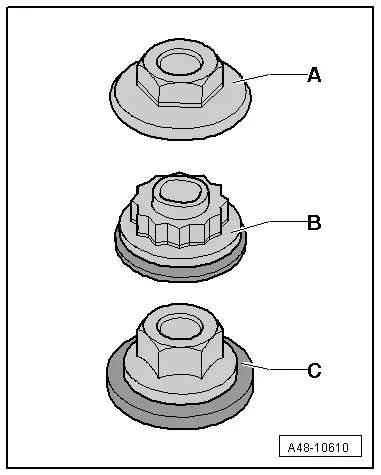

Nut versions for the tie rod ball joint bracket

- Hex collar nut -A-

Tightening specification: 20 Nm 90º.

- Twelve-point combination nut -B-

Tightening specification: 100 Nm

- Hex combi nut -C-

Tightening specifications: 110 Nm