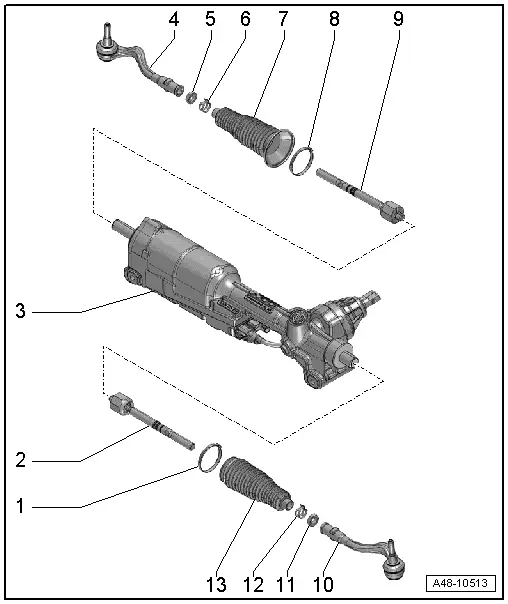

Audi Q5: Steering Gear, Servicing

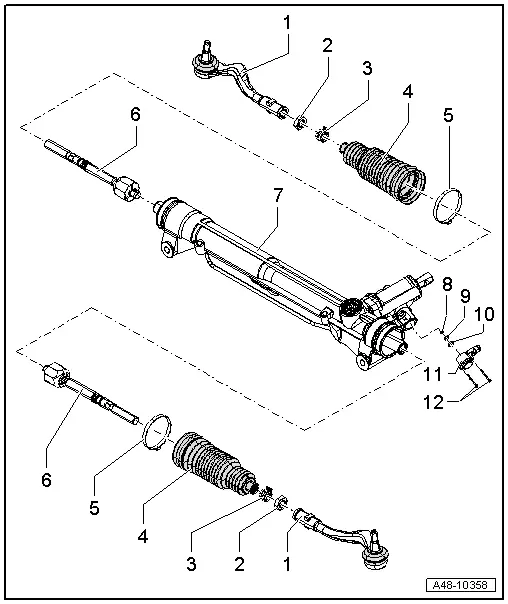

Steering Gear, Electromechanical Steering Gear, Servicing

Note

Note

- Always replace self-locking nuts and bolts.

- Welding or straighten work on any steering components is not permissible.

- Use only Power Steering Gear Grease to lubricate the steering rack (on the pinion side) and the ball paths (on the engine side). Note: there are different types of grease for the left and right. Refer to the Parts Catalog for the allocation.

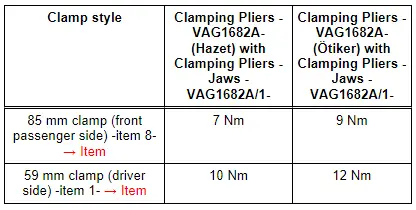

- The clamps -1 and 8- are tensioned to different tightening specifications.

1 - Clamp

- Always replace if removed

- Use the CV Joint Boot Clamp Tool to tension the clamp. Refer to → Fig. "Tensioning the Inner Clamp"

Note

Note

Do not open or bend the new clamp.

- Refer to the Parts Catalog for the version.

2 - Tie Rod

- 100 Nm

- Removing and installing. Refer to → Chapter "Electromechanical Steering Gear Tie Rod, Removing and Installing"

- Grease the joint with Power Steering Gear Grease

3 - Electromechanical Steering Gear

- Removing and installing. Refer to → Chapter "Electromechanical Steering Gear, Steering Gear, Removing and Installing"

- Grease the steering rack with Power Steering Gear Grease Note: there are different types of grease for the left and right. Refer to the Parts Catalog for the allocation.

- There are different versions. Refer to the Parts Catalog.

A removable heat shield mat was installed on the steering gear at start of production. Be sure to install this mat if installing the old steering gear again.

A removable heat shield mat on the steering gear was replaced by a bonded heat shield mat as a running change. It is therefore not necessary to take the mat from the old steering gear and installing on a new steering gear.

A replacement steering gear comes with the bonded heat shield mat.

4 - Tie Rod End

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing, Electromechanical Steering Gear"

- Check dust caps for damage and correct seating

- Check dimension. Refer to → Fig. "Tie rod end check dimension"

5 - Nut

- 80 Nm

- Counterhold on the tie rod end when loosening or tightening

6 - Spring Clamp

- Always replace if removed

- Spring Clamp, Installing.

7 - Boot

- Check for damage

- Always replace if removed

- Coat the inside of the joint boot seats all the way around and evenly with Power Steering Gear Grease before installing. Refer to the Parts Catalog.

- Check the boot seat on the steering gear housing for damage. The steering gear must be replaced if there is damage.

- Must not be twisted when toe is being adjusted

- Make sure it is installed correctly.

- Replacing. Refer to → Chapter "Electromechanical Steering Gear Boot, Removing and Installing".

8 - Clamp

- Always replace if removed

- Use the CV Joint Boot Clamp Tool to tension the clamp. Refer to → Fig. "Tensioning the Inner Clamp".

Note

Note

Do not open or bend the new clamp.

- Refer to the Parts Catalog for the version.

9 - Tie Rod

- 100 Nm

- Removing and installing. Refer to → Chapter "Electromechanical Steering Gear Tie Rod, Removing and Installing"

- Grease the joint with Power Steering Gear Grease

10 - Tie Rod End

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing, Electromechanical Steering Gear"

- Check dust caps for damage and correct seating

- Check dimension. Refer to → Fig. "Tie rod end check dimension"

11 - Locking Nut

- 80 Nm

- Counterhold on the tie rod end when loosening or tightening

12 - Spring Clamp

- Always replace if removed

- Spring Clamp, Installing.

13 - Boot

- Check for damage

- Always replace if removed

- Coat the inside of the joint boot seats all the way around and evenly with Power Steering Gear Grease before installing. Refer to the Parts Catalog.

- Check the seat for the boot on the steering gear for damage before installing. If the steering gear housing is damaged, replace the steering gear.

- Must not be twisted when toe is being adjusted

- Make sure it is installed correctly.

- Replacing. Refer to → Chapter "Electromechanical Steering Gear Boot, Removing and Installing".

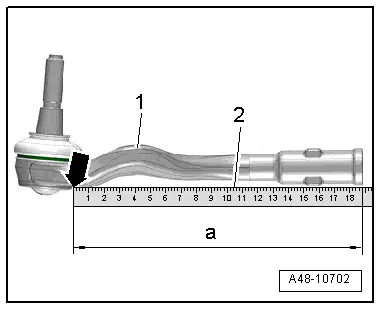

Tie rod end check dimension

- Place a steel ruler -2- on the tie rod end and push it all the up to the edge -arrow- of the tie rod end -1-.

- Replace the complete steering gear with the tie rod and tie rod end if the check dimension -a- is less than 188 mm.

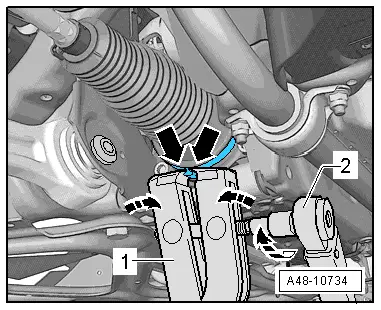

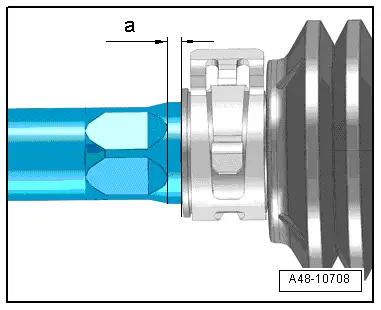

Tensioning the Inner Clamp

- Mount the CV Joint Boot Clamp Tool-1- as illustrated. Make sure that the jaws of the clamp tool are seated in the corners -arrows- of the clamp.

- Tighten the clamp by turning the spindle using a torque wrench -2- (do not tilt the pliers).

- Use torque wrench -2- with 5 to 50 Nm range (for example, Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the thread on the spindle -1- is easy to move. Lubricate with MoS2 grease if necessary.

- If difficult to tighten, for example because of dirty threads, the proper clamping force of the clamping sleeve will not be reached even when tightened to the specification.

Outer Boot Assembly

- Dimension -a- 2 mm.

Steering Gear, Servicing, Hydraulic Power Steering Gear

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Hose Clip Pliers -VAG1921-

- Locking Pliers -VAS6199-

- Steering Gear Grease

Note

Note

- Always replace self-locking nuts and bolts.

- Welding or straighten work on any steering components is not permissible.

- To grease the rack, only use Steering Gear Grease.

1 - Tie Rod End

- There are different versions, with long or short thread on the joint pin; allocation. Refer to the Parts Catalog.

WARNING

WARNING

When replacing, make sure the length of the thread on the tie rod end is sufficient (there must be approximately 5 mm extra thread). If this is not the case, then install a tie rod end with a longer thread pin, allocation Parts Catalog.

- Check dust caps for damage and correct seating

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing, Hydraulic Power Steering Gear"

2 - Nut

- 60 Nm

3 - Spring Clamp

- Always replace if removed

- Version. Refer to the Parts Catalog.

4 - Boot

- Check for damage

- Do not twist after adjusting the toe

- Can be replaced with steering gear installed

- Replacing. Refer to → Chapter "Boot, Removing and Installing, Hydraulic Power Steering Gear".

5 - Clamp

- Always replace if removed

- Clamping Sleeves, Installing.

6 - Tie Rod

- 90 Nm

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing, Hydraulic Power Steering Gear"

- Grease joint with Steering Gear Grease.

7 - Power Steering Gear

- Grease steering rack with Steering Gear Grease.

- There are different versions. Refer to the Parts Catalog.

8 - Strainer

- Always replace if removed

9 - Seal

- Always replace if removed

10 - Seal

- Always replace if removed

11 - Servotronic Solenoid Valve - N119-

- Removing and installing. Refer to → Chapter "Servotronic Solenoid Valve -N119-, Removing and Installing"

- The following values can be checked using theVehicle Diagnostic Tester

- Speed signal

- Power supply from the Vehicle Electrical System Control Module -J519-

- Solenoid valve status

- Measured current for solenoid valve control

- Connect the Vehicle Diagnostic Tester and then select troubleshooting using "Functions/Component selection".

- Then "body".

- "Electrical Equipment"

- "01- On Board Diagnostic (OBD) capable systems".

- Vehicle Electrical System Control Module -J519-

- "Electrical components".

- Servotronic Solenoid Valve -N119-

12 - Bolt