Audi Q5: Hood, Adjusting

Special tools and workshop equipment required

- Gauge - Gap Adjustment -3371-

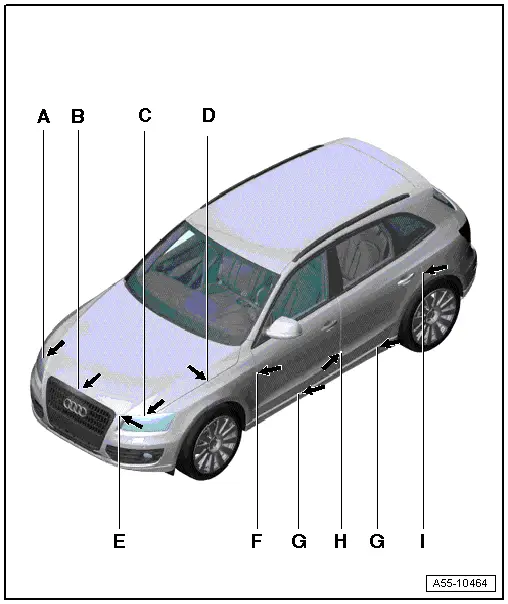

Hood Gap Dimensions

- Dimension -A- = 5.0 mm

- Dimension -B- = 4.5 mm

- Dimension -C-= 5.0 mm

- Dimension -D- = 3.0 mm

- Dimension -E- = 4.5 mm

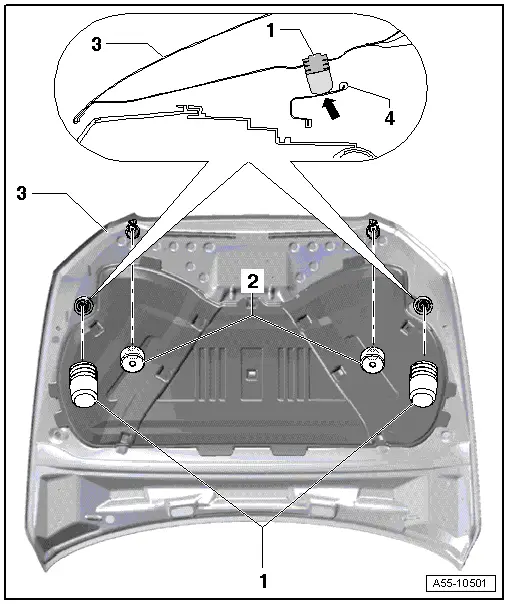

Height Adjustment Stop Buffer

1 - Adjusting Buffer

- Use for adjusting the height on the front side.

- The adjusting buffer -2- must lightly contact the lock carrier when the hood is closed.

2 - Spacer

- The rubber buffers -1- function as a strike guard must not contact the lock carrier when the hood is closed.

3 - Hood

4 - Lock Carrier

Hood Release Lever, Removing and Installing

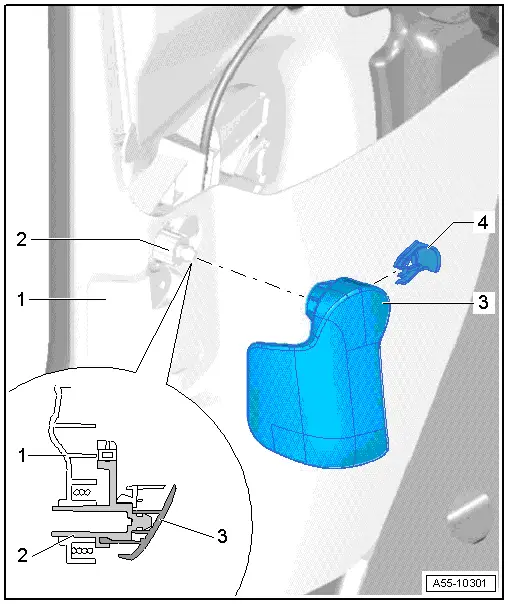

Release Lever Cover, Removing

1 - "A-Pillar" Lower Trim

2 - Hood Release Lever Cover

- First disengage the cable from the coupling inside the engine compartment.

- Pry the clip out of the hood release lever.

- Remove the cover sideways from the operating lever.

3 - Release Lever

4 - Clip

- Press in completely, it must engage.

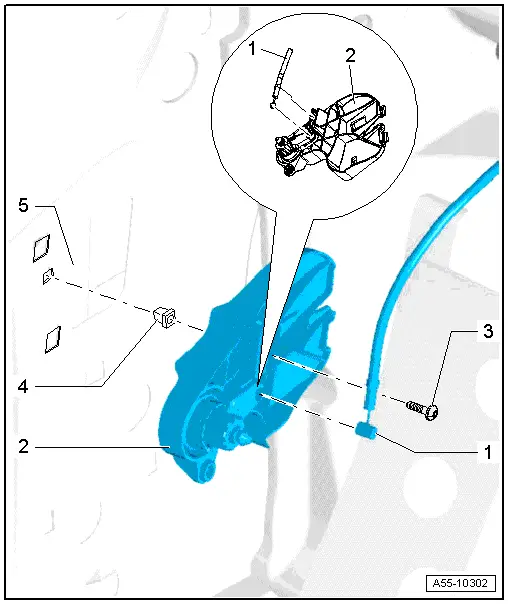

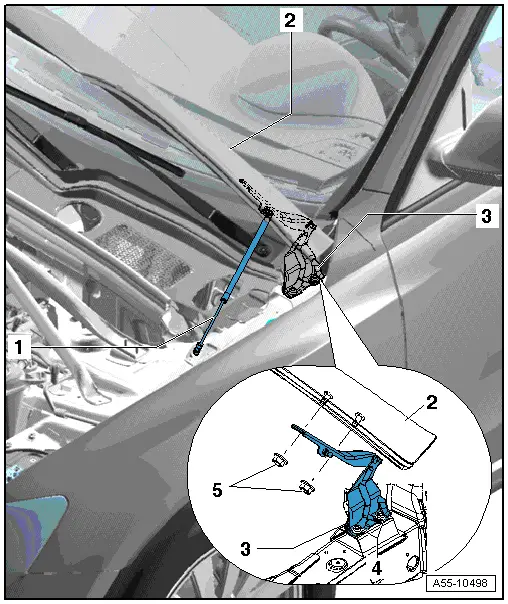

Hood Release Lever, Removing

1 - Release Cable

- Clip the cable bracket into the mounting bracket as shown in the magnified section of the illustration.

2 - Hood Release Lever Bracket

- The hood release lever cover is removed.

- The trim for the "lower A-pillar is removed".

- Remove the screws -3- and disengage the cable -1-.

3 - Bolts

- 2 Nm

4 - Clip

5 - A-Pillar

Catch, Removing and Installing

Striker Pin with Catch, Removing and Installing

Removing

- Remove nuts and remove catch.

Installing

Install in reverse order of removal.

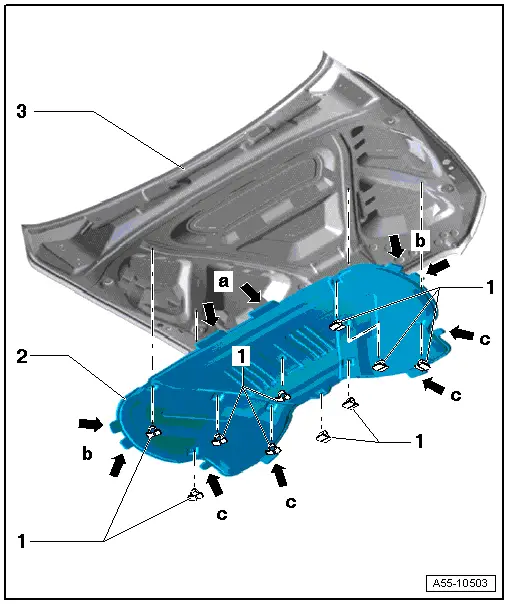

Hinges, Removing and Installing

1 - Gas-Filled Strut

- Install the gas-filled strut tube on the hood side.

- Removing. Refer to → Chapter "Overview - Gas-Filled Strut".

2 - Hood

3 - Nut

- 25 Nm

4 - Hood Hinge

- Before removing a hinge, support the lid or secure it against falling.

- Install the gas-filled strut. Refer to → Chapter "Overview - Gas-Filled Strut".

- Remove the bolts -4- and nuts -5-.

- Install in reverse order of removal.

5 - Nut

- 21 Nm

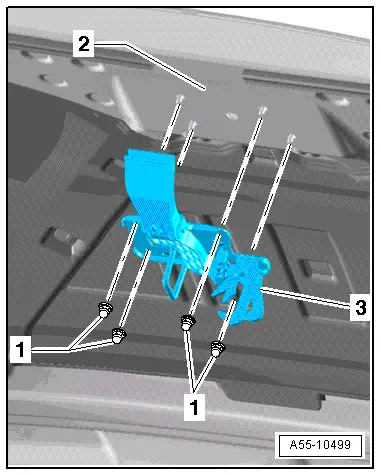

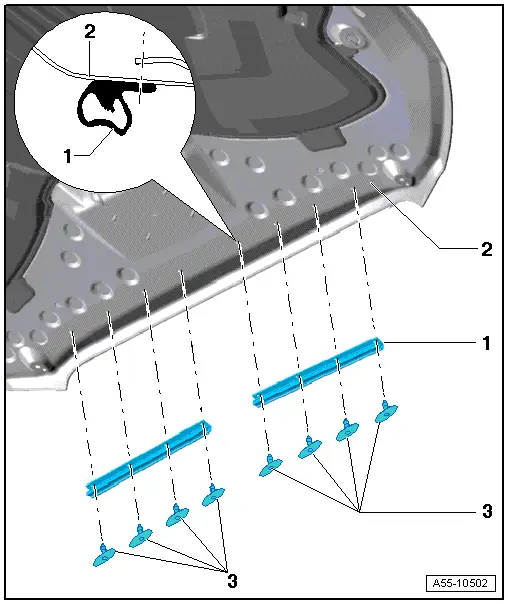

Insulation, Removing and Installing

1 - Clip

2 - Hood Lining

- Installation:

- Slide the lining over the tabs on the rear edge into the holes provided on the inner panel.

- Slide the tabs on the front edge and the sides into place.

- The clips must engage audibly when pressing in.

3 - Door

4 - Clip

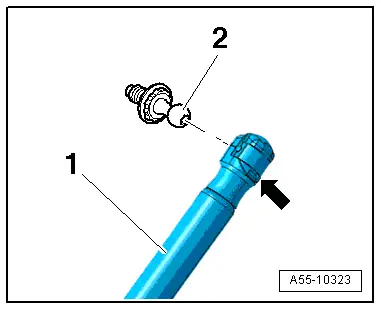

Gas-Filled Strut, Removing and Installing

Removing

- Support the lid or secure it against falling.

- Using a small screwdriver, lift the securing spring -arrow- slightly and remove the gas-filled strut -1- from the upper ball stud -2-.

- Repeat procedure on lower ball stud.

Installing

Note

Note

After completely removing gas-filled strut, ensure correct position when installing: gas-filled strut tube must be engaged on hood side.

- Press gas-filled strut onto ball stud and engage.

Gas-Filled Strut, Releasing Gas

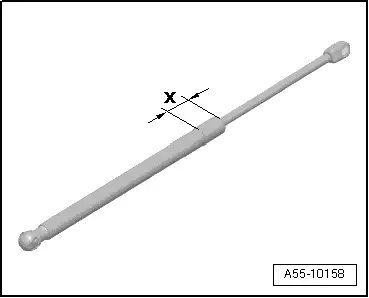

- Clamp gas-filled strut in a vise in area -x- = 50 mm.

WARNING

WARNING

- Clamp only within this area, otherwise accident could occur!

- Wear protective eyewear when sawing.

Note

Note

Cover area of sawn portion with a rag to absorb oil spraying out.

- Cut through the gas-filled strut cylinder within the first third of the overall cylinder length using the piston rod end of the cylinder as a reference point.

Impact Guard, Removing and Installing

Note

Note

The impact guard is also equipped with double-sided adhesive tape.

1 - Door

2 - Impact Guard

- To remove, remove the clip from the hood and then remove the impact guard.

3 - Clip