Audi Q5: Fiber-Optic Cables, Repairing

Caution

Caution

Do not bend the fiber-optic cable too much. The bending radius must be no less than 25 mm.

Fiber optic cables must not be routed over sharp edges.

The fiber-optic cable must not be dirty or touched with bare fingers.

Fiber optic cables may not be heated.

It is not permitted to twist together 2 fiber optic cables or one fiber optic cable with a copper wire.

Protect the connector and the connection box from dust. Place the cap on the trunk.

Determine Position of the Error

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

Procedure

It is very difficult to find the exact location of the problem. Replace the damaged fiber-optic cable and lay a new wire parallel to the defective fiber-optic cable.

Note

Note

- Via the "Guided Fault Finding" it can be determines which component of the fiber-optic cable is damaged.

- A fiber-optic cable that needs repair is represented by a "yellow" color.

- Perform in the "Off-board Diagnostic Information System Service" the "Ring break diagnosis" function in the Vehicle Diagnostic Tester.

- Remove the affected components.

- Disconnect the connector from the components.

- Assemble the fiber-optic cable:

- Refer to → Chapter "Fiber-Optic Cable, Preparing with the Fiber-Optic Conductor Repair Set -VAS6223A-"

- Refer to → Chapter "Fiber-Optic Cable, Preparing with the Fiber-Optic Conductor Repair Set -VAS6223A-"

Fiber-Optic Cable, Preparing with the Fiber-Optic Conductor Repair Set -VAS6223A-

Special tools and workshop equipment required

- Fiber Optic Repair Set -VAS6223B-

- Hose Cutting Pliers -VAS6228-

Checking Remaining Cut Indicator

- Start by checking remaining cut indicator:

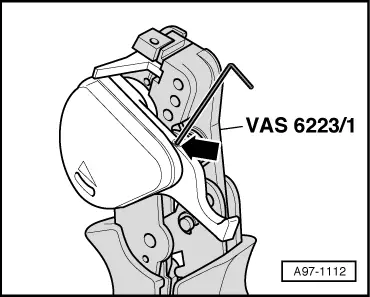

- The Fiber-Optic Repair Set - Pliers -VAS6223/1- cutting device can perform approximately 1260 cuts. The blade is rotated for each further cut.

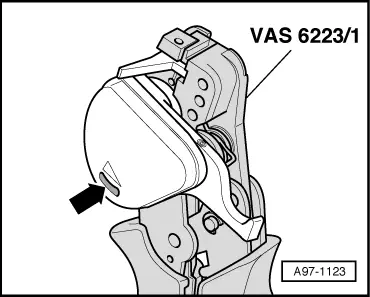

- The remaining cut indicator -arrow - displays the last 150 cuts available.

- Once no further cuts are available, the blade is blocked. It must be replaced. Refer to the Operating Instructions that come with Fiber-Optic Repair Set - Pliers -VAS6223/1-.

Fiber-Optic Repair Set - Pliers -VAS6223/1- Preparing

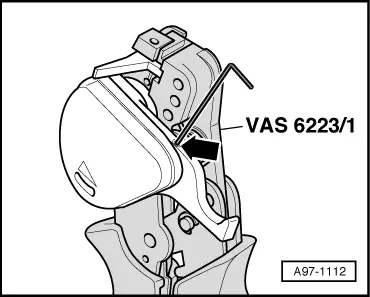

- Release the transport safety device on the cutter by loosening the bolt -arrow-.

Fiber Optic Cable, Cutting to Length

- Establish length of fiber optic cable required.

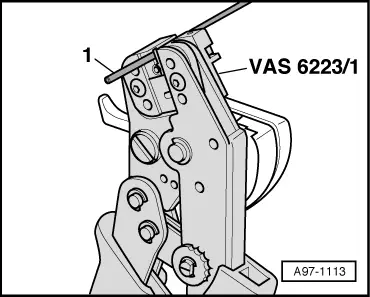

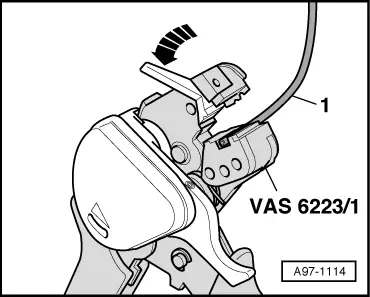

- Open Fiber-Optic Repair Set - Pliers -VAS6223/1- and insert fiber-optic cable -1- into trimming station.

- Close cutting tool to cut fiber optic cable to length.

Stripping

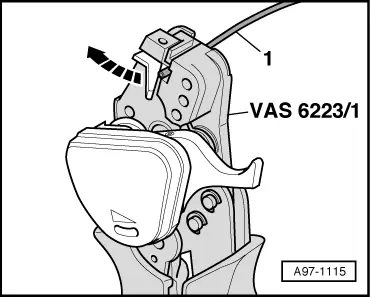

- Open the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

- Stripping lever must be in lower position -arrow-.

- Place the fiber optic cable -1- in the stripping point.

- The end of the fiber-optic cable must be flush with the rear side of the cutting pliers.

- Close Fiber-Optic Repair Set - Pliers -VAS6223/1- until stop and keep closed.

- Lift the stripping lever -arrow- upward.

- Open the cutting tool and take out the fiber-optic cable -1-.

- Detach the separated section of the insulation from the fiber-optic cable.

Precision Cutting (production of optical end face)

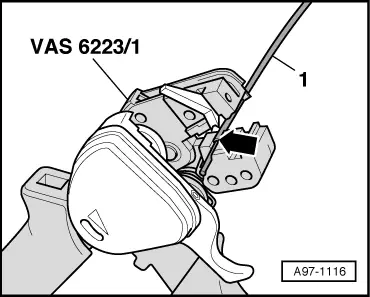

- Slide the fiber-optic cable -1- into the cutting station.

- The insulation must make contact with the cutting point stop -arrow-.

- Close the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

- Press the cutting unit down -arrow-.

- Open Fiber-Optic Repair Set - Pliers -VAS6223/1- and remove fiber-optic cable -1-.

Note

Note

The fiber-optic cable should only be placed on a completely clean surface.

Transport Protection, Activating

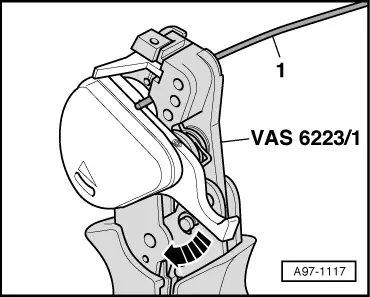

- Close the Fiber-Optic Repair Set - Pliers -VAS6223/1-.

- Tighten the hex socket bolt -arrow- for the transport safety device on the cutter.

Attaching Brass Pin Contact to Fiber-Optic Cable

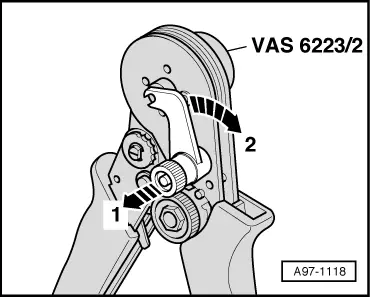

- Open securing lever on Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2--arrow 1- and -arrow 2-.

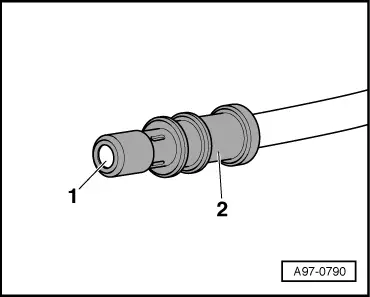

- Insert brass pin contact -1- in the mount.

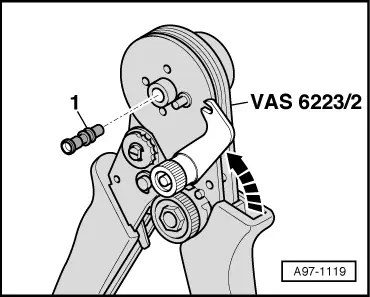

- Close the safety lever on the Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2--arrow-.

- Slide the fiber optic cable -2- into the brass pin contact -1- as far as spring-loaded stop.

- Slide fiber-optic cable further in up to fixed stop and close Fiber-Optic Repair Set - Crimping Pliers -VAS6223/2-.

- Open the crimping pliers for fiber-optic cable and remove the fiber-optic cable with the brass pin contact.

Caution

Caution

Do not bend the fiber-optic cable too much. The bending radius must be no less than 25 mm.

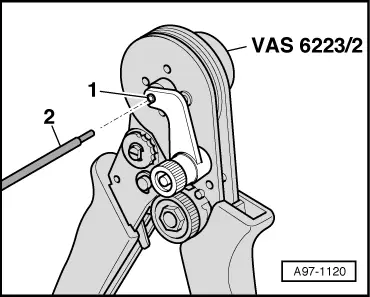

- Make sure the brass pin contact -2- is secured correctly on the fiber-optic cable -1-.

- Four crimp points must be visible at the brass connection pin.

- The brass pin contact must not be able to be removed by hand from the fiber-optic cable.

- The front surface of the fiber-optic cable is 0.01 to 0.1 mm behind the brass pin contact (visual check).

Note

Note

- Connector couplings are available for connecting the fiber-optic cables. Refer to Parts Catalog.

- For installing the new fiber optic cable in the wiring harness connector. Refer to → Chapter "Fiber-Optic Cable, Disconnecting from Wiring Harness Connector".

Corrugated Tube, Install on Fiber Optic Cable.

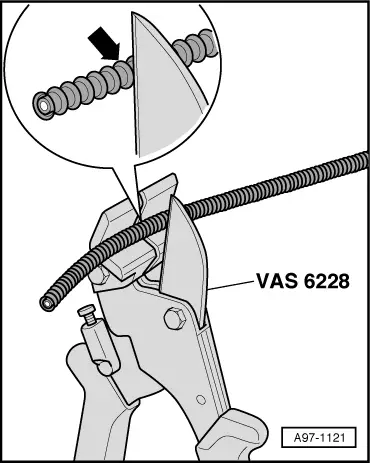

- Cut the corrugated tube to the appropriate length.

- Use the Hose Cutting Pliers -VAS6228- or a sharp knife for cutting.

- The corrugated tube must not be cut through using a side cutter under any circumstances

- The corrugated tube must be cut on the wave peak -arrow-, not in the wave trough.

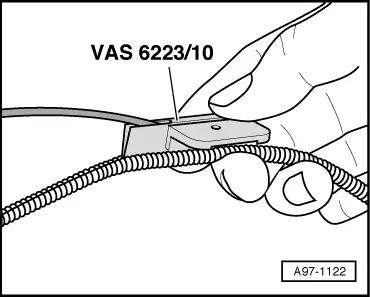

- Guide fiber-optic cable into Fiber-Optic Repair Set - Tube Tool -VAS6223/10- as shown in illustration.

- Position the crimping pliers for fiber-optic cable at the slot on the corrugated tube.

- Slide the crimping pliers for fiber-optic cable along the slot on the circumference of the corrugated tube. The fiber optic cable is then routed in the corrugated tube.