Audi Q5: Stabilizer Bar, Removing and Installing

Removing

- Remove the noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation.

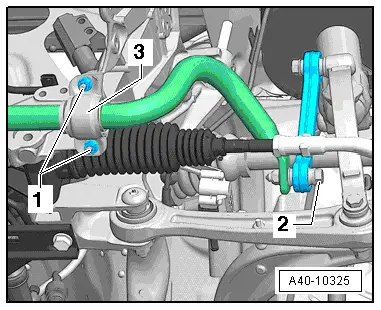

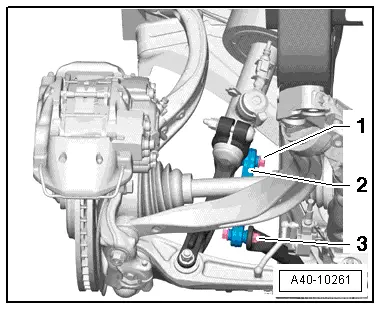

- Disconnect left and right connectors -2-.

- Remove the left and right nuts -1- and the clamp -3-.

- Remove the stabilizer bar.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Bonded rubber bushings have a limited range of motion. Only tighten suspension screws when vehicle is in curb weight or control position.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

Note

Note

- If you replace stabilizer, note chassis version.

- Stabilizer and mounting must be free of grease.

- Install the rubber bushing opening in the direction of the subframe contact surface.

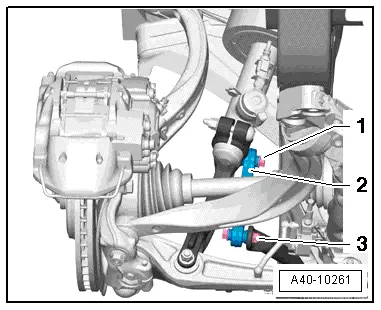

- Install the nuts -1- but do not tighten them.

- Install the left and right threaded connections -2- but do not tighten them.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Tighten connections -1- and -2-.

Coupling Rod, Removing and Installing

Note

Note

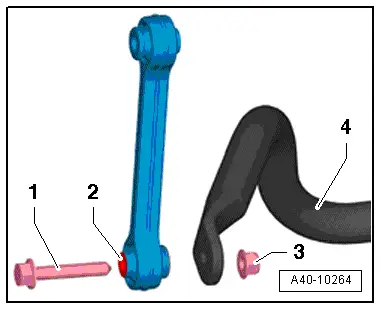

As a running change in MY 2010, aluminum coupling rods were replaced by plastic coupling rods. Do not use different types of coupling rods on the same axle.

Removing

- Disconnect the bolting -1- and -3-.

- Remove the coupling rod -2-.

Installing

Install in reverse order of removal. Note the following:

Note

Note

- Note the installation position of the coupling rod.

- Bonded rubber bushings have a limited range of motion. Only tighten suspension screws when vehicle is in curb weight or control position.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- The bolt -1- for connecting the coupling rod to the stabilizer bar -4- must be attached to the "small" surface -2- of the coupling rod collar and secured with the nut -3-.

- Install the threaded connections -1- and -3- but do not tighten them.

- Wheel bearing, lifting to curb weight position on vehicles with coil springs. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Tighten the threaded connections -1- and -3-.

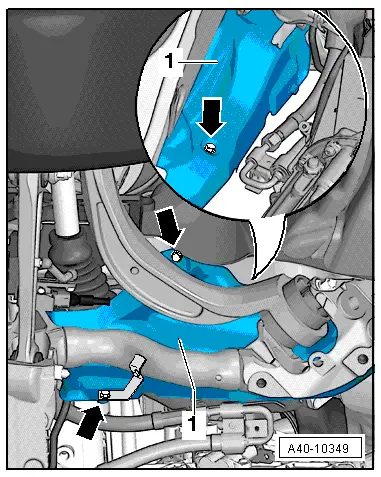

Subframe Heat Shield, Removing and Installing

Removing

- Remove the crossbrace. Refer to → Chapter "Subframe Crossbrace, Removing and Installing".

- Remove the bolts -arrows-.

- Remove the subframe shield -1-.

Installing

Install in reverse order of removal. Note the following:

- Insert the square nuts into the cast recesses before installing the subframe shield -item 16-.