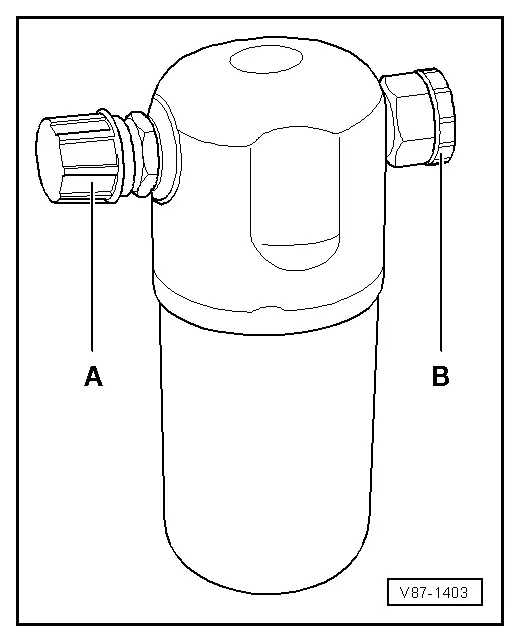

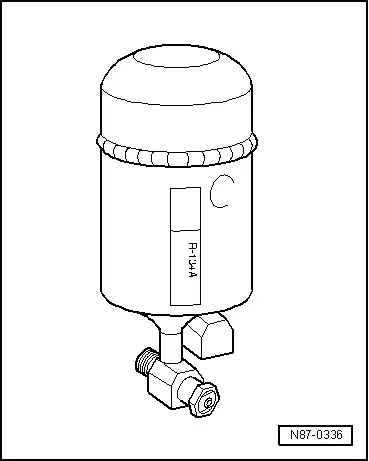

Audi Q5: Reservoir

The reservoir collects the vaporized and gaseous mixture coming from the evaporator to ensure the compressor only receives gaseous refrigerant. Gaseous refrigerant is formed from the vapor.

The refrigerant oil flowing in the circuit is not retained in the reservoir as it has an oil drilling.

Moisture which has entered the refrigerant circuit during repairs will be collected by a filter (desiccant bag) in the reservoir.

Gaseous refrigerant is extracted with oil by the A/C compressor.

Note

Note

- Replace the reservoir if refrigerant circuit has been open for a long time (beyond the normal repair time) and moisture has penetrated inside, or if required due to a specific complaint. Refer to → Chapter "Refrigerant Circuit Components, Replacing".

- Remove the sealing plugs -A- and -B- only immediately before installing.

- A desiccant bag in an unsealed reservoir is saturated with moisture after a short period of time and unusable.

- When installing, note arrow for direction of flow if necessary.

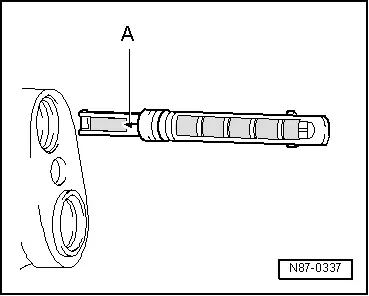

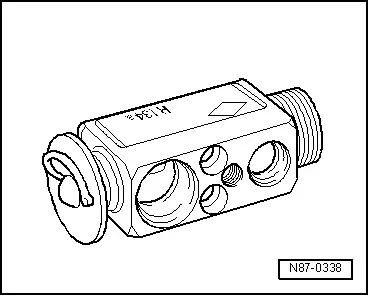

Restrictor

Restrictor in Front of the Evaporator

The restrictor creates a constriction. This restriction reduces the flow and creates high and low pressure sides in the refrigerant circuit. Before the restrictor the refrigerant which is under a higher pressure is warm. After the restrictor the refrigerant which is under a low pressure is cold. Before the restriction there is a strainer for contaminants and after the restriction there is a strainer, to atomize the refrigerant before it reaches the evaporator.

Note

Note

- Arrow -A- on restrictor points to the evaporator.

- Replace after each opening of the circuit.

- There are different versions, therefore pay attention to the different customer service information sources. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit and (vehicle-specific repair manual) and to the Parts Catalog .

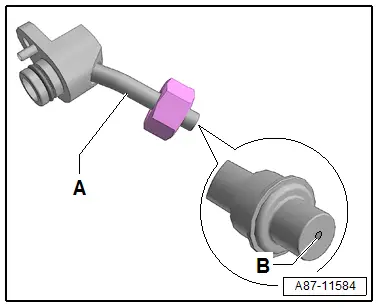

Restrictor in Front of the High Voltage Battery Heat Exchanger (Chiller)

The restrictor creates a constriction. This restriction reduces the flow and creates high and low pressure sides in the refrigerant circuit. Before the restrictor the refrigerant which is under a higher pressure is warm. After the restrictor the refrigerant which is under a low pressure is cold.

Note

Note

- The illustration shows a refrigerant line -A- with a fixed installed restrictor -B- (without a strainer)

- The diameter of the illustrated variable orifice -B- is approximately 0.7 mm. Depending on the version of the refrigerant line this constriction is either installed fixed in the refrigerant line or only inserted. For the inserted version a strainer for flowing deposits may be installed, which can be blocked by the variable orifice.

- Before installing check for debris and if necessary clean or replace.

- There are different versions, therefore pay attention to the different customer service information sources. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit and (vehicle-specific repair manual) and to the Parts Catalog.

Receiver/Dryer

The receiver/dryer collects the fluid drops and then directs them in an uninterrupted stream to the expansion valve. Moisture which has entered the refrigerant circuit during repairs will be collected by the desiccant bag in the receiver/dryer.

Note

Note

- Replace the receiver/dryer if refrigerant circuit has been open for a long time (beyond the normal repair time) and moisture has penetrated inside, or if required due to a specific complaint. Refer to → Chapter "Refrigerant Circuit Components, Replacing".

- Only remove sealing plugs shortly before installation.

- A desiccant bag in an unsealed receiver/dryer becomes saturated with moisture after a short period of time and unusable.

- When installing, note arrow for direction of flow if necessary.

- Depending on the version of the refrigerant circuit, the receiver/dryer is also installed (integrated) either on the condenser or inside the condenser. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit (vehicle-specific repair manual) and the Parts Catalog.

- The procedure is different for each complaint depending on the version of the receiver/dryer and the dryer cartridge. If the receiver/dryer, for example, is attached to the condenser, then it can be replaced complete with the drying cartridge. If the receiver/dryer, for example, is inside the condenser, then the dryer cartridge, and any possible additional filters, can be replaced separately, on most versions. If the receiver/dryer is inside the condenser and there is absolutely no way to replace the reservoir or the dry cartridge individually, then the entire condenser must be replaced. Refer to →Heating, Ventilation and Air Conditioning; Rep. Gr.87 and →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual) and Parts Catalog.

- Depending on the construction of the refrigerant circuit, the receiver can also be secured onto the condenser. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit (vehicle-specific repair manual) and the Parts Catalog.

Expansion Valve

The expansion valve atomizes the streaming refrigerant and controls the flow quantity so that the vapor is gaseous only at the evaporator outlet, depending on the heat transmission.

Note

Note

- Be sure to use the correct part number when replacing the expansion valve. Refer to the Parts Catalog.

- Different characteristic curves matched to the appropriate circuit. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit (vehicle-specific repair manual) and the Parts Catalog.

- Depending on the A/C compressor version, there may be a valve installed on the high pressure side of the A/C compressor, which prevents the liquid refrigerant from flowing back into the compressor once the A/C is turned off. If an A/C compressor with this valve is installed in a vehicle with a refrigerant circuit having an expansion valve, then it may take some time until the pressure in the high pressure side decreases (the expansion is cold and the pressure in the low pressure side quickly increases after it is turned off, the expansion valve closes and the refrigerant flows slowly into the low pressure side). If the A/C compressor is switched on, the pressure on the low pressure side goes down, the expansion valve open and the refrigerant can flow of the low pressure side.

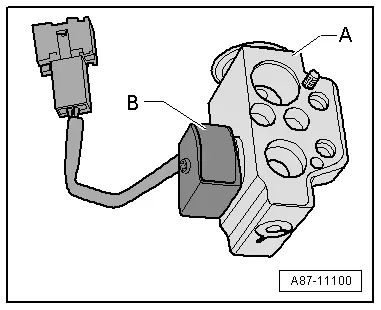

Expansion Valve with Shut-Off Valve

Note

Note

There are different versions of the shut-off valve with different functions and with different names. The following illustrated Hybrid Battery Refrigerant Shut-Off Valve 2 -N517- is for example installed on an Audi Q7 hybrid in the battery cooling module. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; Refrigerant Circuit; System Overview - Refrigerant Circuit.

- The expansion valve -A- with the Hybrid Battery Refrigerant Shut-Off Valve 2 -N517--B- atomizes the streaming refrigerant and regulates the refrigerant flow rate to the evaporator in the battery cooling module for the Hybrid Battery Unit -AX1- so that the vapor becomes gaseous only at the evaporator output, depending on the heat transmission.

- If the Hybrid Battery Refrigerant Shut-Off Valve 2 -N517--B- is activated by the electronics and is open, it lets refrigerant flow through the expansion valve -A- to the evaporator in the battery cooling module.

- The expansion valve -A- with the Hybrid Battery Refrigerant Shut-Off Valve 2 -N517--B- is installed on vehicles with a battery cooling module. It is activated when the A/C system is in operation, if it is necessary to cool the Hybrid Battery Unit -AX1-.

- If the Hybrid Battery Refrigerant Shut-Off Valve 2 -N517--B- is activated by the electronics (for example, by the Battery Regulation Control Module -J840-), it is open and lets the refrigerant flow according to its control characteristic toward the evaporator in the battery cooling module.

- The Hybrid Battery Refrigerant Shut-Off Valve 2 -N517--B- attached to the expansion valve -A- is activated, for example, by the Battery Regulation Control Module -J840-. Refer to → Wiring diagrams, Troubleshooting & Component locations. Use the Vehicle Diagnostic Tester in the "Guided Fault Finding" Function for the A/C System and the Battery Regulation.

- If, for a vehicle with two evaporators (one in the A/C unit and one in the battery cooling module, for example on the Q5 Hybrid), the measured temperature on one of the evaporators corresponds to the specified value or the specified value falls short, but does not reach the required specified value on the other evaporator, the following adjustment is performed: the Battery Regulation Control Module -J840- activates the electric A/C compressor with increased speed (thereby increasing the A/C system cooling output and decreasing the pressure on the low pressure side as well as the evaporator temperature) via the Electric Drive Power and Control Electronics -JX1- and the A/C Compressor Control Module -J842-. If the specified value for the temperature falls short at one of the evaporators, the Battery Regulation Control Module -J840- activates the Hybrid Battery Refrigerant Shut-Off Valve 1 -N516- or the Hybrid Battery Refrigerant Shut-Off Valve 2 -N517-, so that the evaporator which is too cold is no longer supplied with refrigerant. Use the Vehicle Diagnostic Tester in the "Guided Fault Finding" Function for the A/C System.