Audi Q5: Repairing a 0.22 mm 2 Wire with Intermediate Wire Section

Note

Note

For repairing a 0.222 a repair wire can be used as the intermediate wire with a cross section of 0.35-mm2 or 0.5-mm2.

Procedure

- Free up the wire to be repaired at two places approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

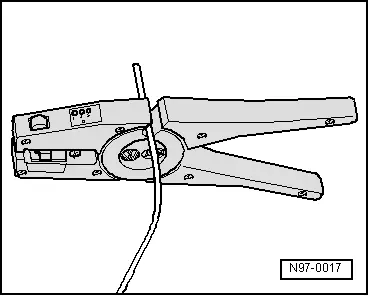

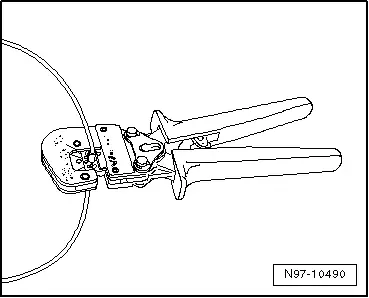

- Route the yellow repair wire next to the damaged wiring harness and cut the repair wire to the required length using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

- Cut damaged wire section from the vehicle-specific single wire.

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 12 to 14 mm for the wire to be stripped.

- Insert the vehicle-specific single wire end from the front into the pliers jaws as far as the stop and squeeze the pliers together completely.

- Open pliers again and remove the stripped wire end.

- Twist bare strands one-half turn.

- Repeat the procedure on the other end of the vehicle-specific individual wire.

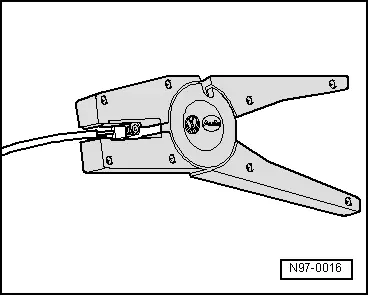

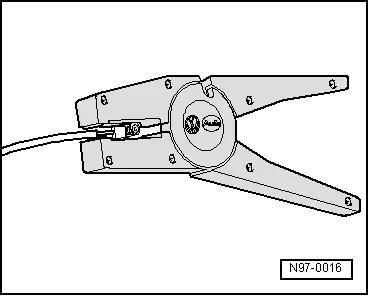

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 6 to 7 mm for the wire to be stripped.

- Insert the yellow repair wire end from the front into the pliers jaws as far as the stop and squeeze the pliers together completely.

- Open pliers again and remove the stripped wire end.

- Repeat this procedure on the other repair wire end.

- For the repair of a 0.22 mm 2 wire, use a small transparent crimp connector from the Wiring Harness Repair Set -VAS1978B-.

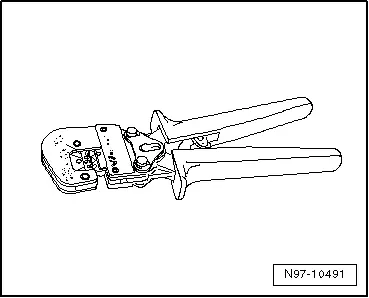

- Use die Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- with Wiring Harness Repair - Crimping Head - .35-2.5mm -VAS1978/1-1- from the Wiring Harness Repair Set -VAS1978B- to crimp the wire.

- Push the small transparent crimp connector on the side of the stripped, non-insulated wire ends of vehicle-specific single wire on the other side of the repair wire stripped wire ends.

- Crimp the crimp connection at both wire ends using crimp pliers.

- Repeat this procedure at the other repair wire end.

Note

Note

Do not crimp wire insulation.

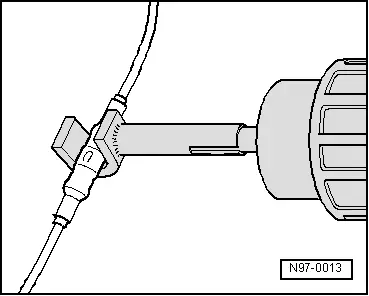

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

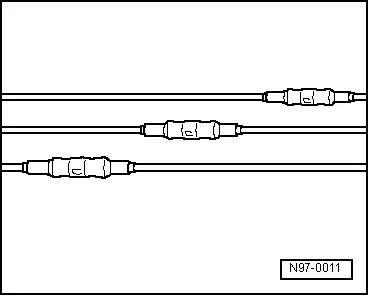

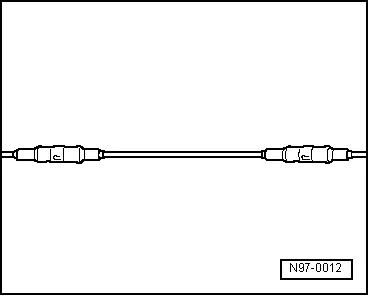

- This is how the completed repair location with the inserted wire and two crimp connectors should look.

Note

Note

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.