Audi Q5: Overview - Wheel Bearing

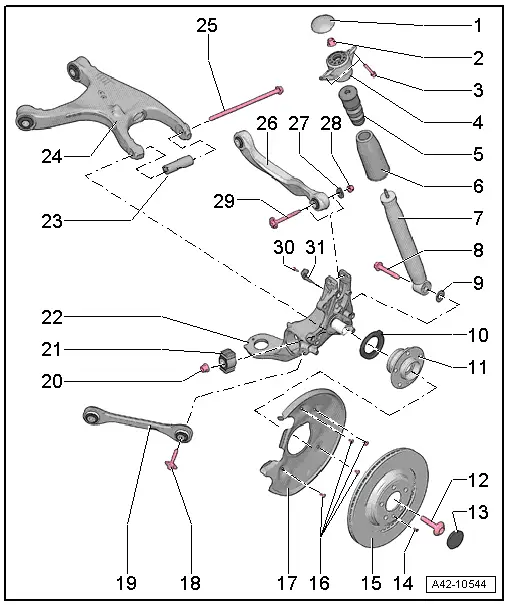

Overview - Wheel Bearing, Vehicles with FWD

1 - Protective Cap

2 - Nut

- 35 Nm

- Always replace if removed

3 - Bolt

- 50 Nm +45º

- Always replace if removed

4 - Upper Shock Absorber Mount

- Installed position.

5 - Stop Buffer

6 - Protective Sleeve

7 - Shock Absorber

- Removing and installing. Refer to → Chapter "Shock Absorber, FWD, Removing and Installing"

8 - Bolt

- 150 Nm +180º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

9 - Washer

- Serves as corrosion protection

- Always use

10 - Front Seal

11 - Wheel Bearing Unit

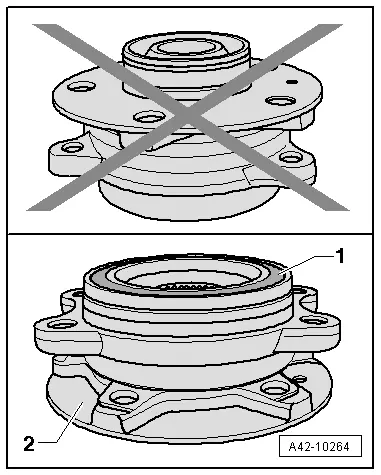

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing. Refer to → Fig. "Avoid contaminating with dirt and damaging the seal when setting down/storing.".

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, FWD, Removing and Installing".

12 - Bolt

- 200 Nm +180º

- Always replace if removed

13 - Protective Cap

- Remove with Puller - Grease Cap -VW 637/2-

- Always replace if removed

14 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Overview - Rear Brakes.

15 - Brake Rotor

16 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Overview - Rear Brakes.

17 - Brake Shield

18 - Bolt

- 90 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

19 - Tie Rod

- There are versions made of aluminum and steel. Refer to the Parts Catalog for the allocation.

- A mixed installation is not permitted

20 - Nut

- Always replace if removed

Caution

Caution

Do not tighten the threaded connection using the nut.

Note

Note

Axle alignment is necessary if the nut is loosened.

21 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Wheel Bearing Housing Bonded Rubber Bushing, Replacing, FWD Vehicles".

22 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing, FWD Vehicles"

23 - Spacer Tube

- Always replace if removed

24 - Lower Transverse Link

25 - Bolt

- 120 Nm +360º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

Note

Note

Axle alignment is necessary if the bolt is removed.

26 - Upper Transverse Link

27 - Shim

28 - Nut

- 95 Nm

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

29 - Bolt

30 - Bolt

- Tightening specification. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Overview - Rear Brakes.

31 - Rear Speed Sensor

Avoid contaminating with dirt and damaging the seal when setting down/storing.

- The wheel bearing -1- must always face up.

- Always set the wheel bearing down on the wheel hub -2-.

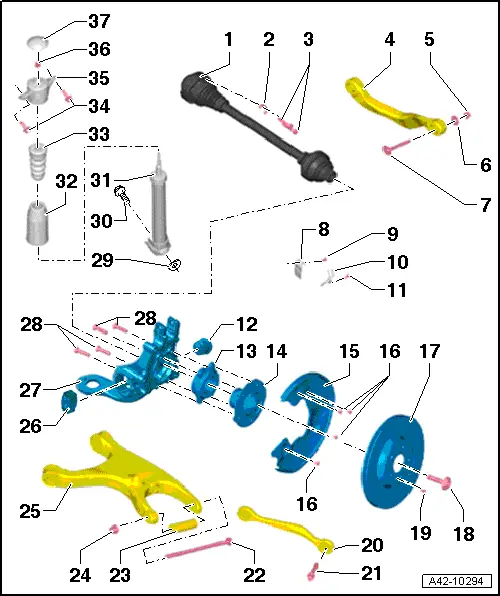

Overview - Wheel Bearing, Vehicles with AWD

1 - Drive Axle

- There are different versions. Refer to the Parts Catalog.

2 - Backing Plate

3 - Bolt

- Tightening specification. Refer to → Chapter "Drive Axle".

4 - Upper Transverse Link

5 - Nut

- 95 Nm

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

6 - Eccentric Washer

7 - Bolt

8 - Bracket

- For the brake hose, brake caliper wiring harness and rear wheel speed sensor wiring harness

9 - Bolt

- 10 Nm

10 - Rear Wheel Speed Sensor

11 - Bolt

- 9 Nm

12 - Bonded Rubber Bushing

- Cannot be exchanged separately

13 - Ball Bearing

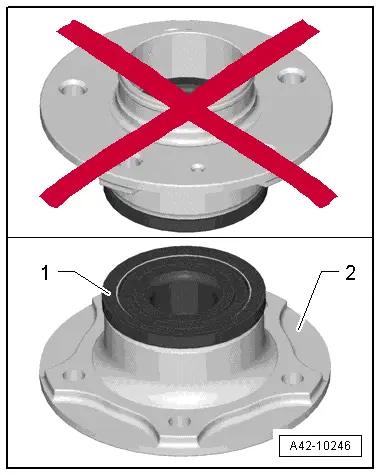

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing.

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, AWD, Removing and Installing".

- Servicing the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Servicing".

14 - Wheel Hub

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing.

- Wheel bearing unit, removing and installing. Refer to → Chapter "Wheel Bearing Unit, AWD, Removing and Installing".

- Servicing the wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, Servicing".

15 - Brake Shield

16 - Bolt

- 10 Nm

17 - Brake Rotor

18 - Collar Screw

- 200 Nm +180º

- Always replace if removed

19 - Bolt

- 5 Nm

20 - Tie Rod

- There are versions made of aluminum and steel. Refer to the Parts Catalog for the allocation.

- A mixed installation is not permitted

21 - Bolt

- 90 Nm +90º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

22 - Bolt

- 120 Nm +360º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

Note

Note

Axle alignment is necessary if the bolt is removed.

23 - Spacer Tube

- Always replace if removed

24 - Nut

- Always replace if removed

Caution

Caution

Do not tighten the threaded connection using the nut.

Note

Note

Axle alignment is necessary if the nut is loosened.

25 - Lower Transverse Link

26 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Wheel Bearing Housing Bonded Rubber Bushing, Replacing, AWD Vehicles".

27 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, AWD, Removing and Installing"

28 - Bolt

- 80 Nm +90º

- Always replace if removed

29 - Washer

- Serves as corrosion protection

- Always use

30 - Bolt

- 150 Nm +180º

- Always replace if removed

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

31 - Shock Absorber

- Removing and installing. Refer to → Chapter "Shock Absorber, AWD, Removing and Installing"

32 - Protective Sleeve

33 - Stop Buffer

34 - Bolt

- 50 Nm +45º

- Always replace if removed

35 - Upper Shock Absorber Mount

- Installed position. Refer to → Fig. "Upper shock absorber mount installation position"

36 - Nut

- 35 Nm

- Always replace if removed

37 - Protective Cap

Avoid contaminating with dirt and damaging the seal when setting down/storing

- The wheel bearing -1- must always face up.

- Always set the wheel bearing down on the wheel hub -2-.

The same procedure also applies to the wheel bearing without a wheel hub.