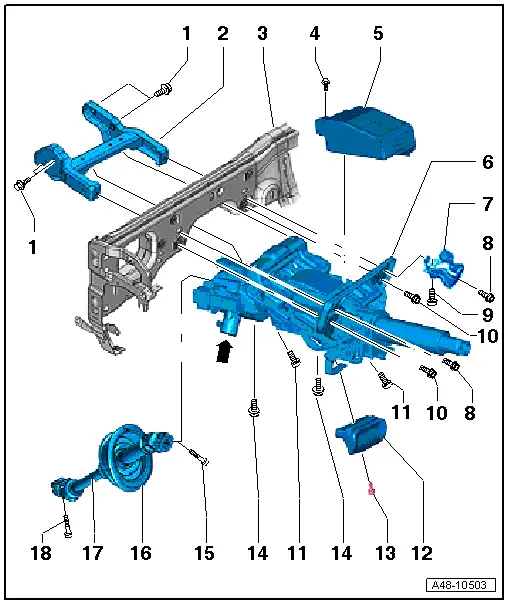

Audi Q5: Overview - Steering Column

Audi Q5 Type 8R (2008 - 2017) Service Manual / Chassis / Suspension, Wheels, Steering / Steering / Overview - Steering Column

1 - Bolt

- Tightening specification. Refer to → Body Interior; Rep. Gr.70; Instrument Panel Central Tube; Overview - Instrument Panel Central Tube.

2 - Bracket

3 - Central Tube

4 - Bolt

- 5 Nm

5 - Electronic Steering Column Lock Control Module -J764-

- Installed on vehicles with steering lock system

- Removing and installing. Refer to → Chapter "Electronic Steering Column Lock Control Module -J764-, Removing and Installing"

- If the Electronic Steering Column Lock Control Module -J764- was replaced, the following work must performed using the Vehicle Diagnostic Tester. Select the program in "Guided Functions" and follow the prompts on the screen.

6 - Steering Column

- Depending on the version of the steering (with or without dynamic steering) different versions of the steering columns are installed. Refer to the Parts Catalog.

- Actuator -arrow- installed on vehicles with dynamic steering.

- The actuator -arrow- must not be loosened or separated from the steering column.

- The actuator and the steering column are one component; they are replaced together. Refer to the Parts Catalog.

- An "active steering safety lock actuator (dynamic steering)" is installed on the actuator -arrow-.

- Active steering safety lock actuator (dynamic steering). Refer to → Chapter "Active Steering Safety Lock (Locking Magnet), Removing and Installing".

- If the steering column and adjuster were replaced, then it is necessary to perform a basic setting on the dynamic steering. Refer to → Chapter "Dynamic Steering Basic Setting".

- Removing and installing. Refer to → Chapter "Steering Column, Removing and Installing"

- Check for damage. Refer to → Chapter "Steering Column, Checking for Damage".

7 - Right Knee Bar

- Installed depending on the market

8 - Bolt

- 20 Nm

- Quantity: 2

- Depending on the market, the knee bar is bolted on the right driver side

- Follow the assembly sequence when installing. Refer to → Fig. "Follow the assembly sequence when installing".

9 - Bolt

- Tightening specification. Refer to → Body Interior; Rep. Gr.70; Instrument Panel Central Tube; Overview - Instrument Panel Central Tube.

10 - Bolt

- 20 Nm

- Quantity: 2

- Follow the assembly sequence when installing. Refer to → Fig. "Follow the assembly sequence when installing".

11 - Bolt

- 20 Nm

- Quantity: 2

- Follow the assembly sequence when installing. Refer to → Fig. "Follow the assembly sequence when installing".

12 - Handle

13 - Bolt

- 3 Nm

14 - Bolt

- 20 Nm

- Quantity: 2

- Follow the assembly sequence when installing. Refer to → Fig. "Follow the assembly sequence when installing".

15 - Bolt

- 30 Nm +90º

- Always replace if removed

- The threaded hole for the bolt must always be cleaned, for example, with a thread cutter

16 - Sealing Boot

- Align the positioning arrow to the "12 o'clock position".

17 - Steering Intermediate Shaft

- Removing and installing. Refer to → Chapter "Steering Intermediate Shaft, Removing and Installing"

18 - Bolt

- 30 Nm +90º

- Always replace if removed

- The threaded hole for the bolt must always be cleaned, for example, with a thread cutter