Audi Q5: Overview - Driveshaft

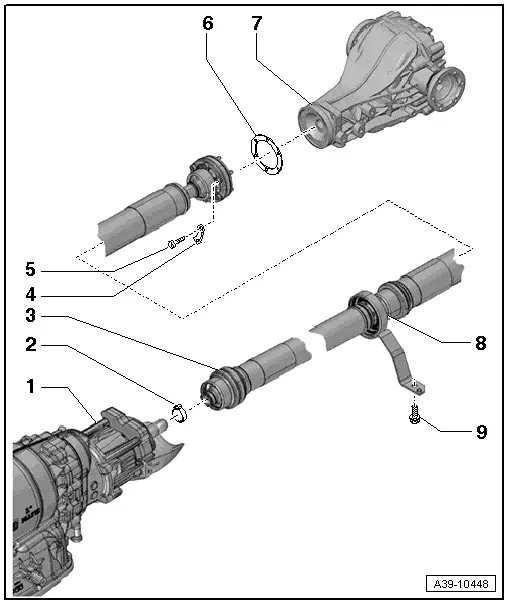

Overview - Driveshaft, Mounted On Transmission Side

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- The attached driveshaft can only be separated from the transmission if it is completely removed.

- No repair work can be carried out on the driveshaft with the exception of removing, installing and adjusting.

- Always store and transport the driveshaft when it is fully extended.

- The driveshaft can be bent all the way to the center joint without force. Bending the joint forcibly all the way can damage the center joint and/or the protective boot.

- If the driveshaft is separated only from the rear final drive, the driveshaft must be tied up or supported. If necessary, the driveshaft can be bent as far as the end stop of the center without force.

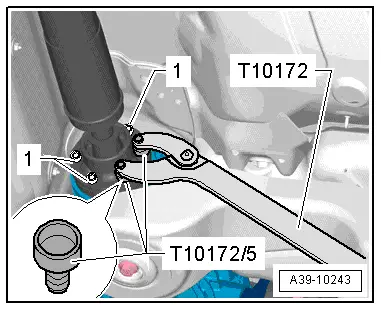

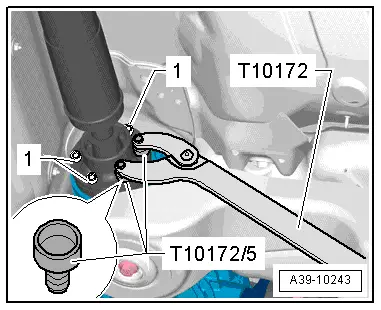

- Use the Counterhold - Kit - Multiple Use - T10172- with the Adapters - T10172/5- to loosen or tighten the driveshaft bolts.

- Always remove or install the driveshaft horizontally from the transmission output shaft.

- Tightening sequence for the attaching the driveshaft to the rear final drive. Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence".

Should there be complaints (noise, vibration), do the following before replacing the driveshaft:

- Make sure the intermediate bearing is free of tension.

- Remove the driveshaft bolts from the rear final drive. Attaching the driveshaft according to the tightening sequence Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence".

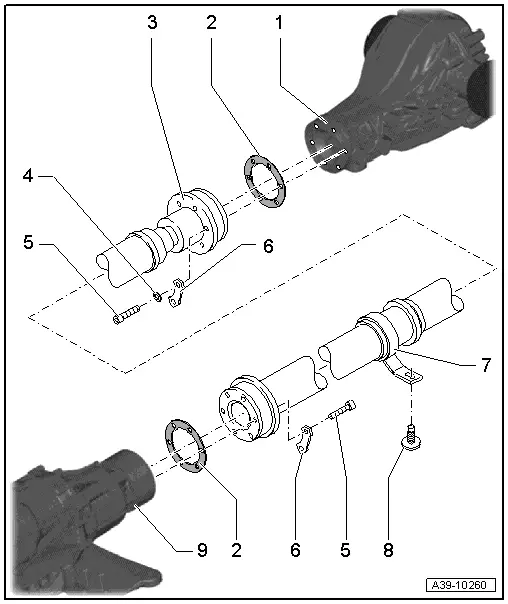

1 - Transmission

2 - Hose Clamp

- Replacing

3 - Driveshaft

- Removing and installing. Refer to → Chapter "Driveshaft, Removing and Installing, Driveshaft Connected on Transmission Side".

- Removing and installing on the rear final drive. Refer to → Chapter "Drive Shaft, Removing and Installing from Rear Final Drive".

- Replace the boot. Refer to → Chapter "Boot, Replacing".

4 - Locking Plate

5 - Bolt

- Self-locking

- Always replace.

- The threads in the flange shaft on the rear final drive must be cleaned of locking fluid residue. Use a thread tap to clean.

Final Drive 0BC, 0BD, 0BF

- M8 x 45

- Tightening specification and sequence. Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence"

Final Drive 0BE

- M10 x 45 x 1

- Tightening specification and sequence. Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence"

6 - Seal

- Replace a damaged seal.

- A seal for which the rubber coating has come loose must be replaced

- Clean the flange shaft and position the seal

- Pay no attention to the different colored sides for the installation

7 - Rear Final Drive

- Removing and installing. Refer to → Chapter "Final Drive".

8 - Intermediate Bearing

9 - Bolt

- 20 Nm

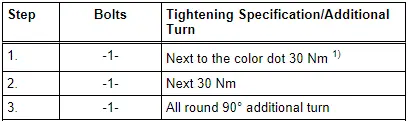

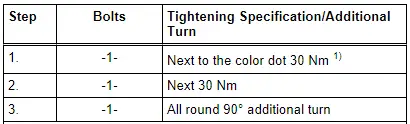

Driveshaft to Rear Final Drive - Tightening Specification and Sequence

- Always replace the driveshaft bolts -1-.

- Counterhold with Counterhold - Kit - Multiple Use -T10172- and Counterhold - Kit - Adapter 5 -T10172/5-.

- Tighten the bolts -1- in three steps:

1) By doing this, the CV joint is pushed slightly to the opposite side and imbalance is avoided.

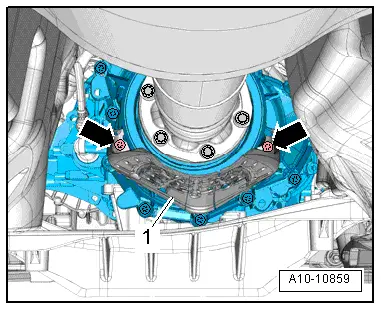

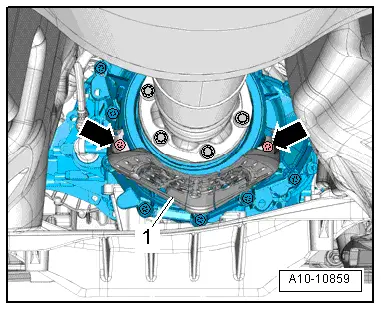

Driveshaft Heat Shield - Tightening Specification

- Tighten the bolts -arrows- to 24 Nm.

Overview - Driveshaft, Bolts On Transmission Side

Note

Note

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- No repair work can be carried out on the driveshaft with the exception of removing, installing and adjusting.

- Always store and transport the driveshaft when it is fully extended.

- The driveshaft can be bent all the way to the center joint without force. Bending the joint forcibly all the way can damage the center joint and/or the protective boot.

- If the driveshaft is separated only from the transmission or the rear final drive, the driveshaft must be tied up by the end or otherwise supported. If necessary, the driveshaft can be bent as far as the end stop of the center without force.

- Label the position of all the parts to each other before removing them. Install in the same position otherwise the imbalance will be excessive and the bearings could get damaged causing rumbling noises.

- Use the Counterhold - Kit - Multiple Use - T10172- with the Adapters - T10172/5- to loosen or tighten the driveshaft bolts.

- After detaching the driveshaft from the rear final drive, do not reinstall the balance disc (thicker washer between the backing plate and the internal multi-point bolt), if applicable.

- If there are concerns (noises, vibrations), check the intermediate bearing for tension before replacing the drive axle.

1 - Rear Final Drive

- Removing and installing. Refer to → Chapter "Final Drive".

2 - Seal

- Replace a damaged seal.

- A seal for which the rubber coating has come loose must be replaced

- Clean the flange shaft and position the seal

- Pay no attention to the different colored sides for the installation

3 - Driveshaft

- Removing and installing. Refer to → Chapter "Driveshaft, Removing and Installing, Driveshaft Bolted on Transmission Side".

- Removing and installing on the transmission. Refer to → Chapter "Driveshaft on Transmission, Removing and installing, Driveshaft Bolted on Transmission Side".

- Removing and installing on the rear final drive. Refer to → Chapter "Drive Shaft, Removing and Installing from Rear Final Drive".

4 - Balance Disc

- Not on every vehicle

- May be installed between the multi-point socket bolt -item 5- and the backing plate -item 6- on the rear final drive.

- If fitted, balance disc must not be installed when driveshaft has been detached from rear final drive.

5 - Bolt

- Always replace.

- Self-locking

- Always clean the threaded holes in the flange shafts. Use a thread tap.

- On the rear final drive:

- Tightening specification and sequence. Refer to → Fig. "Driveshaft to Rear Final Drive - Tightening Specification and Sequence"

- At the transmission:

- 30 Nm + 90º

6 - Locking Plate

7 - Intermediate Bearing

8 - Bolt

- 20 Nm

9 - Transmission

Driveshaft to Rear Final Drive - Tightening Specification and Sequence

- Always replace the driveshaft bolts -1-.

- Counterhold with Counterhold - Kit - Multiple Use -T10172- and Counterhold - Kit - Adapter 5 -T10172/5-.

- Tighten the bolts -1- in three steps:

1) By doing this, the CV joint is pushed slightly to the opposite side and imbalance is avoided.

Driveshaft Heat Shield - Tightening Specification

- Tighten the bolts -arrows- to 24 Nm.