Audi Q5: Shock Absorber, Servicing

Shock Absorber, FWD, Servicing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Shock Absorber Set -T10001-

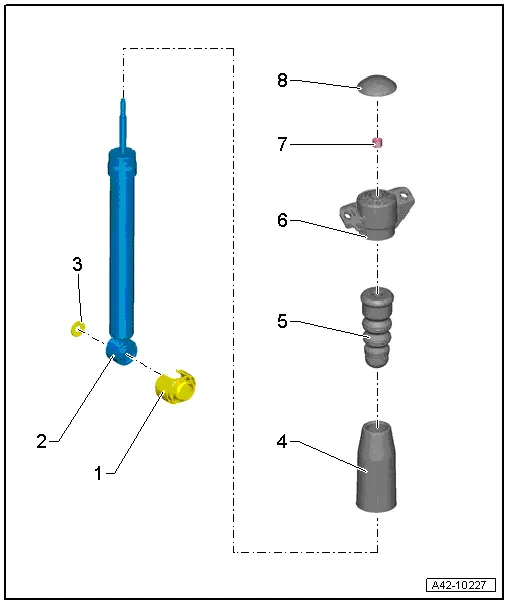

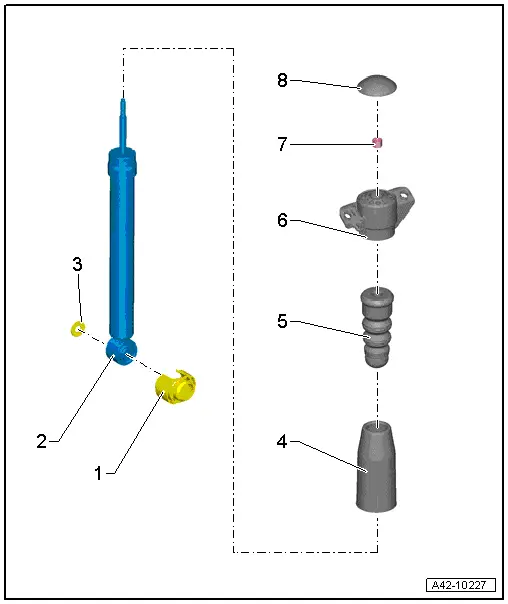

1 - Stone Chip Protection

2 - Shock Absorber

- Only shock absorbers with the same part number may be installed on the left and right

- Removing and installing. Refer to → Chapter "Shock Absorber, AWD, Removing and Installing"

- There are different versions of the suspension. Refer to → Chapter "Explanations of Production Control Numbers (PR Number)".

- Always vent and drain faulty shock absorbers before disposal. Refer to → Chapter "Rear Shock Absorbers, Venting and Emptying".

- Shock Absorber, Checking. Refer to → Chapter "Repair Information".

3 - Washer

- Always use

4 - Protective Pipe

5 - Stop Buffer

6 - Upper Shock Absorber Mount

- Installed position.

7 - Nut

- 35 Nm

- Always replace if removed

- Loosening and Tightening.

8 - Cover

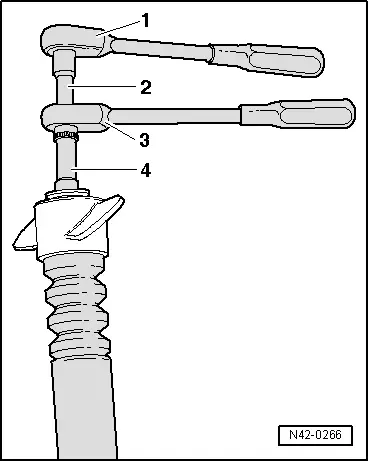

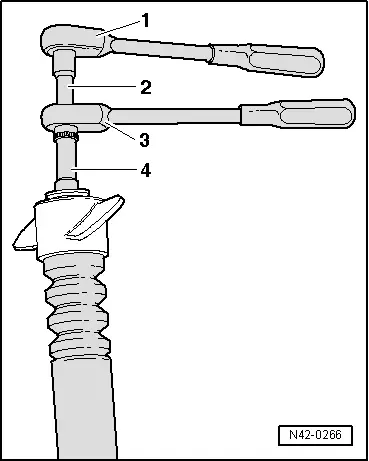

Loosening and tightening the nut

1 - Ratchet (commercially available)

2 - Shock Absorber Set - Extension with Counter Holder 1 -T10001/9-

3 - Shock Absorber Set - Reversible Ratchet -T10001/11-

4 - Shock Absorber Set - Socket -T10001/1-

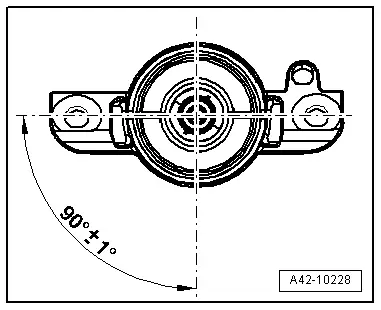

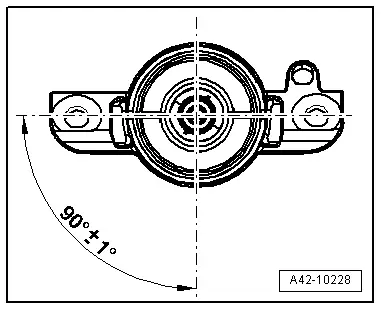

Upper shock absorber mount installation position

- Install the upper shock absorber mount so it is rotated 90º to the lower shock absorber mount.

Shock Absorber, AWD, Servicing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Shock Absorber Set -T10001-

1 - Stone Chip Protection

2 - Shock Absorber

- Only shock absorbers with the same part number may be installed on the left and right

- Removing and installing. Refer to → Chapter "Shock Absorber, AWD, Removing and Installing"

- There are different versions of the suspension. Refer to → Chapter "Explanations of Production Control Numbers (PR Number)".

- Always vent and drain faulty shock absorbers before disposal. Refer to → Chapter "Rear Shock Absorbers, Venting and Emptying".

- Shock Absorber, Checking. Refer to → Chapter "Shock Absorbers, Checking when Removed".

3 - Washer

- Always use

4 - Protective Pipe

5 - Stop Buffer

6 - Upper Shock Absorber Mount

- Installed position. Refer to → Fig. "Upper shock absorber mount installation position"

7 - Nut

- 35 Nm

- Always replace if removed

- Loosening and Tightening. Refer to → Fig. "Loosening and tightening the nut"

8 - Cover

Loosening and tightening the nut

1 - Ratchet (commercially available)

2 - Shock Absorber Set - Extension with Counter Holder 1 -T10001/9-

3 - Shock Absorber Set - Reversible Ratchet -T10001/11-

4 - Shock Absorber Set - Socket -T10001/1-

Upper shock absorber mount installation position

- Install the upper shock absorber mount so it is rotated 90º to the lower shock absorber mount.