Audi Q5: Overview - Drive Axle

Audi Q5 Type 8R (2008 - 2017) Service Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Drive Axle

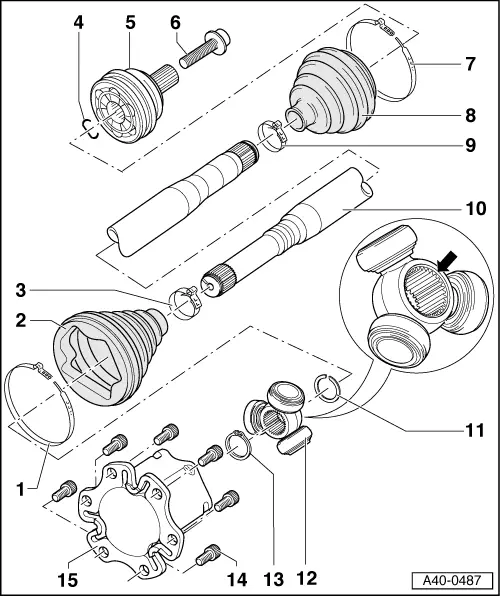

Peened triple roller joint AAR 2600 i with 88 mm outer CV joint

Peened triple roller joint AAR 3300 i with 100 mm outer CV joint

1 - Clamp

- Always replace if removed

- For tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".

2 - Protective Boot with Triple Roller Joint Adapter

- Protective joint boot must fit in groove and on joint contour.

- Before tightening clamp, briefly raise CV boot to allow pressure to equalize.

3 - Clamp

- Always replace if removed

- For tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".

4 - Circlip

- Always replace if removed

- Insert before mounting in ring groove (not visible with joint installed)

- Before installing CV joint, align sealing ring in center with opening facing upward.

5 - Outer CV Joint

- Replace only as a complete unit.

- For removing.

- Checking.

- For installing.

- For greasing.

- When installing the joint on the profile shaft, the splines on the profile shaft must be lightly coated with grease used in joint.

6 - Bolt

- 200 Nm +180º

- Always replace if removed

- Before installing, clean the threads in the CV joint with a tap.

- Follow the sequence when loosening and tightening the threaded connection between the drive axle and the wheel hub. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

7 - Clamp

- Always replace if removed

- For tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".

8 - CV Boot for Outer CV Joint

- Check for tears and scuffing

- Before tightening clamp, briefly raise CV boot to allow pressure to equalize.

9 - Clamp

- Always replace if removed

- For tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".

10 - Drive Axle

- Removing and installing. Refer to → Chapter "Drive Axle, Removing and Installing".

11 - Circlip

- Allocation. Refer to the Parts Catalog.

12 - Triple Roller Star

The chamfer -arrow- faces the drive axle splines.

- When installing triple roller star on axle shaft, splines on axle shaft must be lightly coated with grease used in joint.

13 - Circlip

- Always replace if removed

- Insert in shaft groove

14 - Bolt

- Allocation. Refer to the Parts Catalog.

- Tightening specification: -item 22-.

15 - Joint

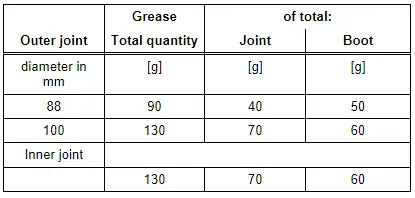

Grease quantity and type

Grease joint when replacing CV boot.

Pack the joint with grease. Refer to the Parts Catalog.

Note

Note

Note that the outer and inner joints use different types of grease.