Audi Q5: Input Shaft Seal, Replacing, 0BD

- The flange/driveshaft used before must be installed.

- If the flange/driveshaft is also being replaced, do the following. Refer to → Chapter "Flange Shaft Ring, Replacing, 0BD".

Special tools and workshop equipment required

- Puller - Multiple Use -VW391-

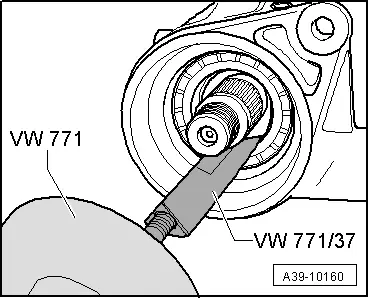

- Slide Hammer Set -VW771-

- Slide Hammer Set - Hook -VW771/37-

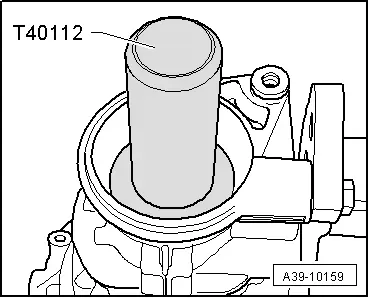

- Seal Installer - Driveshaft Flange - T40112-

- Retainer - Drive Flange - 3028-

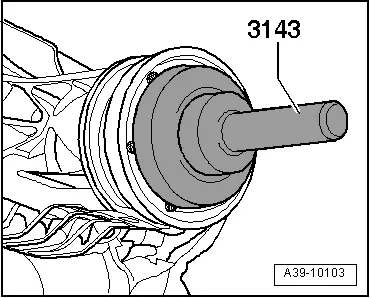

- Seal Installer - Wheel Bearing Seal - 3143-

- Holding Fixture - Gearbox Adapter -T10235-

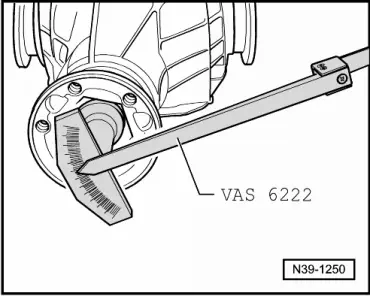

- Friction Gauge - VAS6222-

- Inductive Heater -VAS6414-

- Sealing Grease -G 052 128 A1-

- Locking Fluid - AMV 185 101 A1-

- Three M8 x 25 bolts

- Two M10 x 40 bolts

Removing

- The flange/driveshaft seal can replaced only when the rear final drive is removed.

Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Remove the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

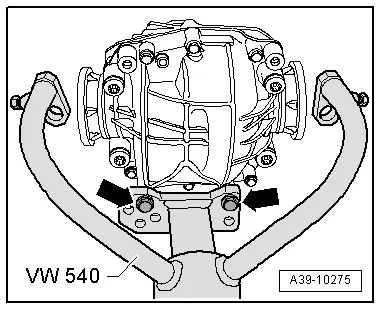

- Secure the rear final drive to the Holding Fixture -VW540- using the bolts (M10 x 40) -arrows-.

- Measure the friction torque before loosening the pinion nut.

- Write down this value.

Caution

Caution

If, during the repair, the flange/driveshaft must be replaced, then this measured must be adjusted once again. Refer to → Chapter "Flange Shaft Ring, Replacing, 0BD".

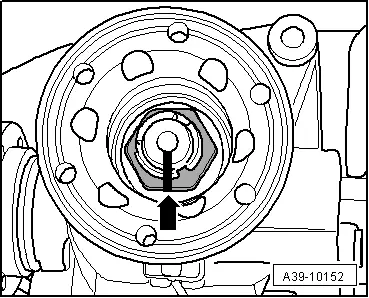

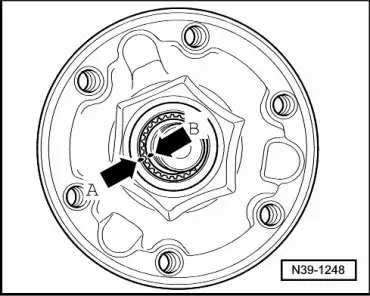

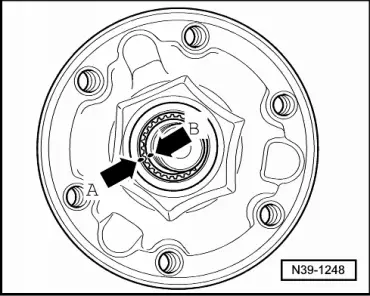

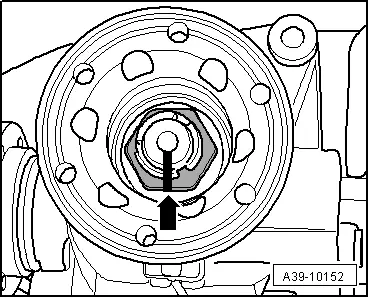

- Mark the position of the drive pinion nut to the drive pinion -arrow-.

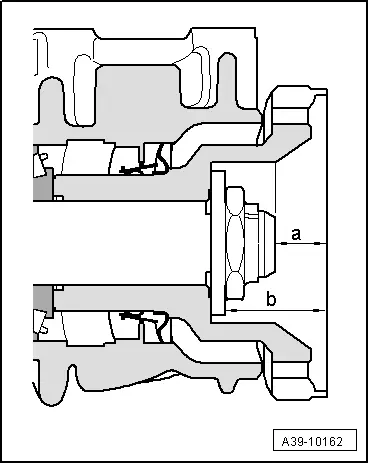

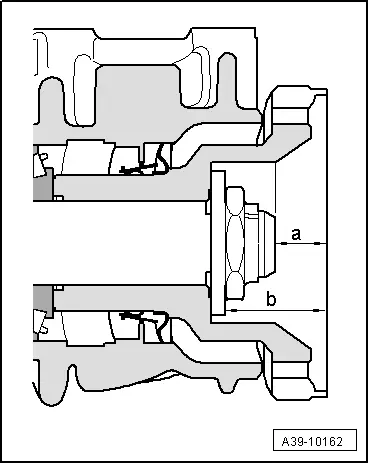

Determining dimension "-a-" and dimension "-b-"

- Flange distance to the pinion = dimension -a-

- Distance from the flange to the drive pinion nut = dimension -b-

- Write down the established dimensions.

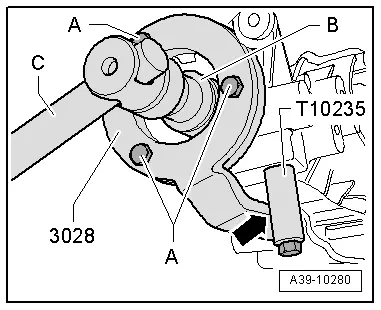

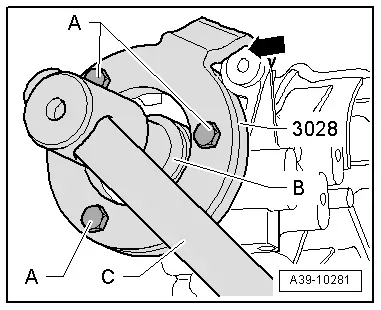

- Secure the Retainer - Drive Flange -3028- to the flange/driveshaft with the bolts -A-.

- Secure the Holding Fixture - Gearbox Adapter -T10235- in the threaded hole below the flange/driveshaft.

- Loosen the pinion nut, at the same time the Retainer - Drive Flange -3028- must be supported on the Holding Fixture - Gearbox Adapter -T10235--arrow-.

- Count the number of turns when removing the drive pinion nut and write it down.

-A -Three M 8 x 25 bolts

-B -32 mm Socket

-C -Toggle

- Mark the position of the flange/driveshaft -arrow A- to the drive pinion -arrow B-.

- Place the Drip Tray underneath.

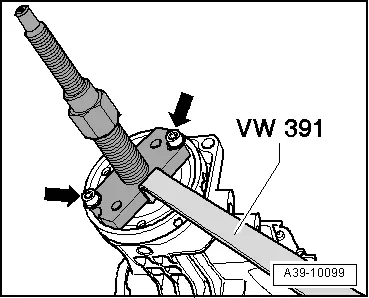

- Secure the Puller - Multiple Use -VW391- using the Two bolts M 8 x 25 -arrows-.

- Remove the flange/driveshaft.

- Remove the shaft seal.

- Clean the threads on the drive pinion.

Installing

Install in reverse order of removal. Note the following:

- Coat outer edge of the seal with gear oil.

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Drive in new shaft seal as far as stop without tilting it.

- Warm the flange/driveshaft to approximately 80 ℃ (176 ºF) using an Inductive Heater -VAS6414-.

- Align the markings on the flange/driveshaft -arrow A- and the drive pinion -arrow B-.

- Install the flange/driveshaft.

- Insert the old pinion nut with Locking Fluid -AMV 185 101 A1-.

- Secure the Retainer - Drive Flange -3028- to the flange/driveshaft with the bolts -A-.

- When tightening the pinion nut, the Retainer - Drive Flange -3028- must be supported on the housing brace -arrow-.

-A -Three M 8 x 25 bolts

-B -32 mm Socket

-C -Toggle

- Install the drive pinion nut using the number of turns noted earlier and tighten to the position marked -arrow-.

Perform the measuring check - check dimension -a- and dimension -b-.

- The measurement may differ by +- 0.2 mm.

- Install the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

- Check the gear oil in rear final drive. Refer to → Chapter "Gear Oil, Checking Level, 0BD".