Audi Q5: Flange Input Shaft Ring, Replacing

Flange Input Shaft Ring, Replacing, 0BC

- The ring can only be replaced with the input shaft removed.

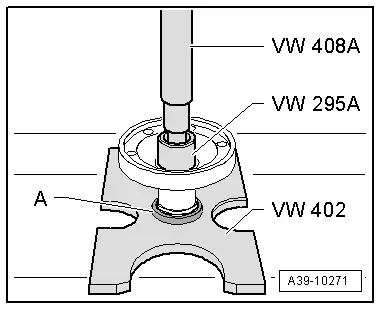

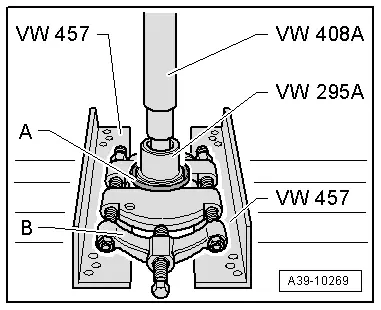

Special tools and workshop equipment required

- Bearing/Bushing Installer - Multiple Use -VW295A-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Support Channels -VW457-

- -3-Separating device 12 to 75 mm, for example Puller - Kukko Quick Action Separating Tool - 12-75mm -17/1-

- Input shaft removed. Refer to → Chapter "Input Shaft Seal, Replacing, 0BC".

Remove the Ring -A- from the Flange/Driveshaft

B - Puller, for example, Puller - Kukko Quick Action Separating Tool - 12-75mm -Kukko 17/1-

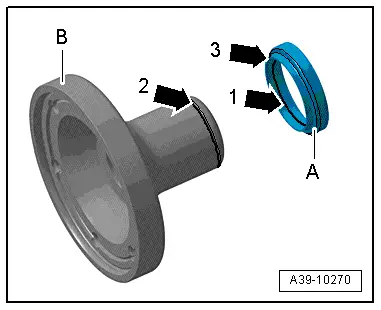

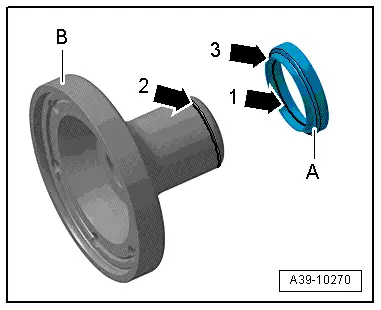

Installation Location of the Protective Ring -A- on the Flange/Driveshaft

- The ridge -arrow 1- on the protective ring -A- must fit into the groove -arrow 2- on the flange -B-. The smaller outer circumference -arrow 3- faces the flange.

Install the Protective Ring -A- onto the Flange/Driveshaft.

- The protective ring -A- must fit into the groove all around the flange. Refer to → Fig. "Installation Location of the Protective Ring -A- on the Flange/Driveshaft".

Flange Input Shaft Ring, Replacing, 0BD

- The ring can only be replaced with the input shaft removed.

Special tools and workshop equipment required

- Press Plate -VW402-

- Press Piece - Rod -VW407-

- Press Piece - Multiple Use -VW412-

- Bearing Installer - Multiple Use -40 - 20-

- Separating tool 22 to 75 mm, such as -17/1-

- Input shaft removed. Refer to → Chapter "Input Shaft Seal, Replacing, 0BD".

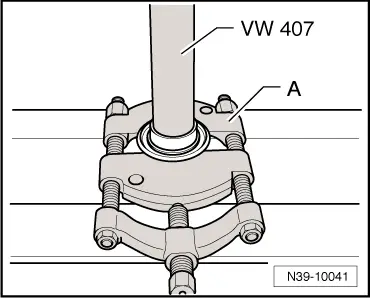

Press the Protective Ring off the Flange/Driveshaft

A - Separating Tool - 22-115mm, such as Puller - Kukko Quick Action Separating Tool - 22-115mm -17/2-

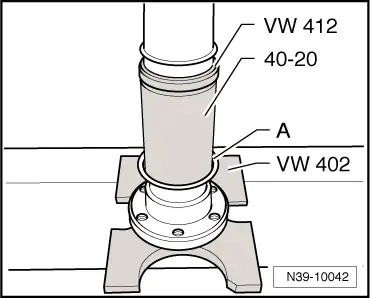

Install the Protective Ring -A- onto the Flange/Driveshaft

- Protective ring -A- installation position: the protective ring notch points upward to the Bearing Installer - Multiple Use -40 - 20-.

Flange Input Shaft Ring, Replacing, 0BE, 0BF

- The ring can only be replaced with the input shaft removed.

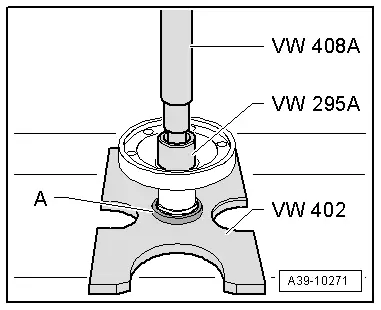

Special tools and workshop equipment required

- Bearing/Bushing Installer - Multiple Use -VW295A-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Support Channels -VW457-

- -3-Separating tool 22 to 75 mm, such as Puller - Kukko Quick Action Separating Tool - 12-75mm -17/1-

- Input shaft removed. 0BE (refer to → Chapter "Input Shaft Seal, Replacing, 0BE".) or 0BF (refer to → Chapter "Input Shaft Seal, Replacing, 0BF".)

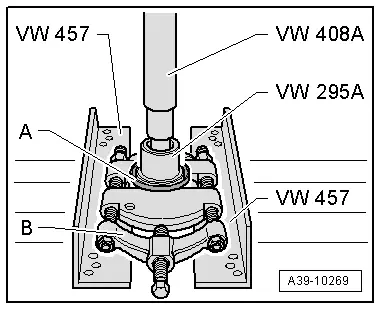

Remove the Ring -A- from the Flange/Driveshaft

B - Separating Tool - 12-75mm, such as Puller - Kukko Quick Action Separating Tool - 12-75mm -17/1-

Installation Location of the Protective Ring -A- on the Flange/Driveshaft

- The ridge -arrow 1- on the protective ring -A- must fit into the groove -arrow 2- on the flange -B-. The smaller outer circumference -arrow 3- faces the flange.

Install the Protective Ring -A- onto the Flange/Driveshaft

- The protective ring -A- must fit into the groove all around the flange. Refer to → Fig. "Installation Location of the Protective Ring -A- on the Flange/Driveshaft".