Audi Q5: A/C System, Operating after Charging

Note

Note

- If the mechanically driven Air Conditioning (A/C) compressor was removed, rotate it approximately 10 times by hand before using it for the first time (during or after installing, for example before installing the belt) to prevent damage caused by liquid impact when first switched on (any oil in compressor cylinder is forced out on rotation).

- If the electronically driven A/C compressor was removed, activate it after filling the A/C compressor before the A/C system on via the "basic setting, compressor cut-in" function for the Guided Fault Finding. Use the Vehicle Diagnostic Tester in the "Guided Fault Finding" Function for A/C System and Battery Regulation. This prevents the A/C compressor from being damaged, for example, by liquid impact when it is first switched on (any oil in the A/C compression chamber is forced out).

- The vehicle engine drives the mechanically driven A/C compressor via a belt or shaft. The electronically driven A/C compressor is driven via an electric motor attached directly to the A/C compressor (for example on hybrid vehicles).

Operating an A/C System with a Mechanically Driven A/C Compressor

- Start engine with compressor switched off (version with A/C clutch).

- Set compressor to minimum output, for example, "Econ" or A/C off mode (version with no A/C clutch with regulating valve).

- Wait until idle speed has stabilized.

- Switch on the compressor and operate the system for at least two minutes at idling speed.

- If necessary, check pressures in the refrigerant circuit using the A/C service station.

- Turn the engine off.

- Screw out the hand wheel on the quick-release coupling adapter.

- Disconnect the charging hoses from the refrigerant circuit.

- Install the caps.

Operating an A/C System with an Electrically Driven A/C Compressor

- Operate the A/C compressor using "basic setting, compressor cut-in" in Guide Fault Finding. Use the Vehicle Diagnostic Tester"Guided Fault Finding" A/C System and Battery Regulation.

Additionally on vehicles with an electric operated valves in the refrigerant circuit, which cannot be opened without power (for example the Audi Q7 e-tron):

- Via the Vehicle Diagnostic Tester the electrically activated valves which do not open without power for the operation of the A/C system enable the activation of these valves via the respective control module (to open or close) using the Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Note

Note

On vehicles with high-voltage system and additional functions of the A/C system ("heat pump operation" or "cooling the high-voltage battery") valves may be installed in the refrigerant circuit which cannot be opened without power. These valves are opened and closed for example via a step motor and after switching off the ignition are no longer activated. To completely drain, correctly discharge and charge the refrigerant circuit no areas may be closed, for this reason the valves must be opened before these procedures. After finishing work on the activation of these valves are enabled via the respective control module. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; Refrigerant Circuit; System Overview - Refrigerant Circuit and using the Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

All

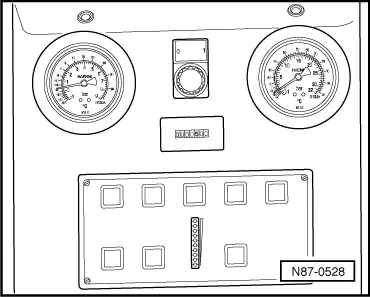

- After the basic setting and If necessary, check pressures in refrigerant circuit using A/C service station. Refer to → Chapter "A/C Service Station, Connecting for Measuring and Testing".

- Screw out the hand wheel on the quick-release coupling adapter.

- Disconnect the charging hoses from the refrigerant circuit.

- Install the caps.

Refrigerant to Service Station Reservoir (Charging Cylinder or Reservoir Bottle), Transferring

- The work procedure is always to be performed as described in the operating instructions for the Air Conditioning (A/C) service station.

- A certain quantity of refrigerant is specified as charge for each air conditioning system. To ensure that neither too much nor too little refrigerant is added (either would reduce the cooling output), the charging cylinder has a scale indicating the weight.

- The volume of a refrigerant changes as a function of pressure. The scale must therefore be set according to the pressure in the charging cylinder.

Note

Note

Do not completely drain the reservoir (charging cylinder or bottle) as the liquid column boundary layer cannot be traced in the tube during filling (outside visible range).

WARNING

WARNING

Do not overfill. A completely filled reservoir (charging cylinder or bottle) will explode when the temperature rises.

Service Station, Draining

Note

Note

- If it is necessary to drain the service station (for example, due to extraction of contaminated refrigerant), all filters and dryers must always be replaced (do not remove filter and dryer from the air-tight packaging until immediately before installation to minimize moisture absorption).

- Refrigerant containers filled with contaminated used refrigerant are referred to as "Recycling containers".

- Thoroughly evacuate the recycling containers prior to initial filling with refrigerant (if there is air in a refrigerant container it is not to be filled with refrigerant).

- Different types of refrigerant may not be mixed together (refrigerant mixtures cannot be recycled and are to be disposed of). If there is any doubt about the composition of the contents of the container, the refrigerant recycling company is to be informed accordingly.

Caution

Caution

- When filling recycling containers (compressed-gas containers), observe applicable regulations, technical rules and laws.

- Recycling containers are never to be overfilled. Overfilled containers do not have a sufficient gas cushion to accommodate the liquid expansion caused by the effects of heat. There is a danger of rupture.

- To ensure safety, make exclusive use of recycling containers fitted with a safety valve.

- Recycling containers must be weighed on calibrated scales during the filling process. The maximum permissible capacity is 75% (charge factor 0.75) of the charge weight indicated on the recycling container (the possibility of refrigerant oil entering the recycling container along with the refrigerant cannot be ruled out).