Audi Q5: Vacuum System, Checking

Tests and Test Requirements

Special tools and workshop equipment required

- Brake Servo Tester -VAS6721-

The following checks will be helpful when performing Fault Finding if there are complaints regarding the brake booster or the so-called "hard brake pedal".

The following components are included in the check:

- Brake Booster

- Seal between the master brake cylinder and the brake booster

- Check Valve

- Vacuum hoses and connectors

- Vacuum pump (if equipped)

Keep the geographical surrounding in mind when evaluating the measured results. The higher above sea level, the lower the air pressure.

Always observe all test requirements before checking the vacuum system:

- Check all the vacuum hoses for damage (for example, tears or damaged caused by animals) and make sure they are secure

- Maintain clean working conditions when working on the vacuum system

- Clean the engine compartment before starting, if necessary

Brake Booster Tester, Connecting

- Remove the vacuum hose from the brake booster.

- Pressing the brake pedal a few times beforehand makes it easier to remove the vacuum hose.

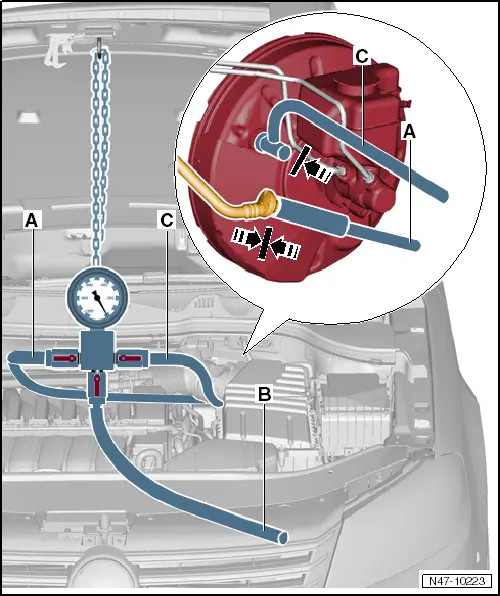

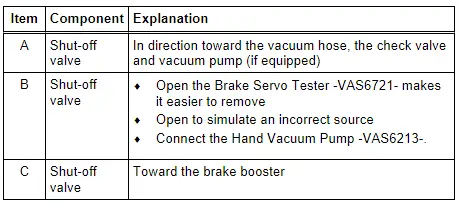

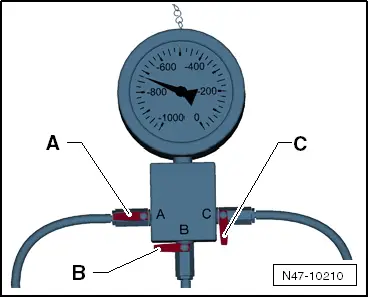

- Connect the Brake Booster -VAS6721- as shown in the following illustrations.

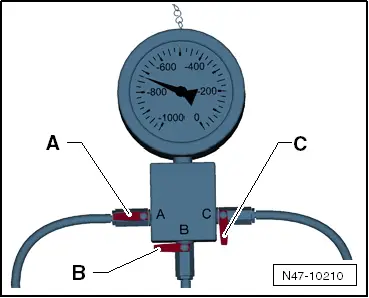

- Connect the Brake Servo Tester -VAS6721- hose -A- to the vacuum hose and push the adapter -C- into the brake booster.

Vacuum, Checking

Note

Note

- The average earth atmospheric air pressure at sea level (N. N.) is 1013 mbar and it decreases dramatically at higher altitudes (approximately 100 mbar every 1000 meters higher) Local and time fluctuations will influence the vacuum.

- Idling the engine has a negative effect on creating a vacuum.

- Check all the vacuum hoses beforehand for damage (for example, tears or damaged caused by animals) and make sure they are secure

- Connect the Brake Servo Tester -VAS6721-. Refer to → Chapter "Brake Booster Tester, Connecting".

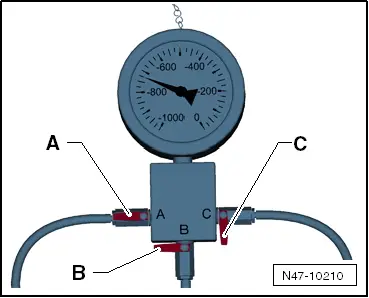

- Open the shut-off valve -A-.

- Close the shut-off valves -B+C-.

- Start the warm (above 60 ºC) engine and press the accelerator pedal one time quickly (engine RPM higher than 2,000).

- Read the measured value displayed.

Normally (see note) the vacuum should be between 600 and 950 mbar (depending on the engine installed).

Check the vacuum system for leaks if the measured value is not reached, even though all requirements (see notes).

- Create the vacuum using a Hand Vacuum Pump -VAS6213- for comparison purposes. Refer to → Chapter "Vacuum, Creating with Hand Vacuum Pump".

Opening the shut-off valve -B- makes it easier to remove the hose connections and the adapter.

Leak Test

Note

Note

- The average earth atmospheric air pressure at sea level (N. N.) is 1013 mbar and it decreases dramatically at higher altitudes (approximately 100 mbar every 1000 meters higher) Local and time fluctuations will influence the vacuum.

- Idling the engine has a negative effect on creating a vacuum.

- Check all the vacuum hoses beforehand for damage (for example, tears or damaged caused by animals) and make sure they are secure

- Connect the Brake Servo Tester -VAS6721-. Refer to → Chapter "Brake Booster Tester, Connecting".

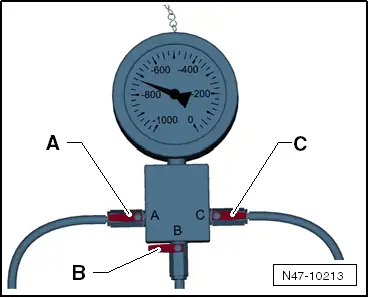

- Open the shut-off valve -A-.

- Close the shut-off valves -B+C-.

- Start the warm (above 60 ºC) engine and press the accelerator pedal one time quickly (engine RPM higher than 2,000).

- Normally (see note) the vacuum should be between 600 and 950 mbar (depending on the engine installed).

- Open the shut-off valve -C- and evacuate the brake booster.

- Turn off the engine.

- Read the measured value displayed and write it down.

- The vacuum may drop 400 mbar within 12 hours.

If the drop in vacuum is greater, check the....

1 - Brake Booster

or in the

2 - Check valve, vacuum hoses and connections and vacuum pump/intake manifold

for leaks.

The vacuum will drop considerably within a few seconds if there are large leaks.

Checking the vacuum near the brake booster:

- Close the shut-off valve -A- after creating the vacuum to test the brake booster vacuum.

Vacuum test near the check valve, vacuum hoses and connections and vacuum pump/intake manifold

- Close the shut-off valve -C- after creating the vacuum to check the vacuum system of the Brake Servo Tester -VAS6721- up to the intake manifold or up to the vacuum pump.

Opening the shut-off valve -B- makes it easier to remove the hose connections and the adapter.

Vacuum, Creating with Hand Vacuum Pump

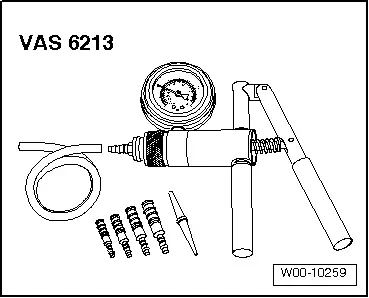

In certain situations, the vacuum can be created using a Hand Vacuum Pump -VAS6213- instead of using the engine or a vacuum pump.

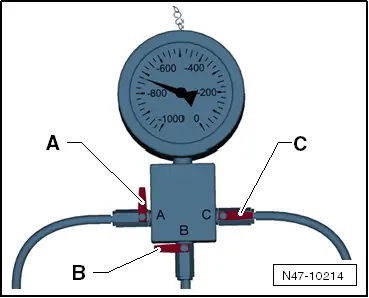

- To do so, connect the Hand Vacuum Pump -VAS6213- to the vacuum hose on the connection -B- on the Brake Servo Tester -VAS6721-.

- Open the shut-off valve -B-.

- Create the vacuum using the Hand Vacuum Pump -VAS6213- until a vacuum between 600 and 950 mbar on the Brake Servo Tester -VAS6721- is displayed.

- Perform the tests.

Electric Vacuum Pump, Removing and Installing

It is not possible to service the Brake System Vacuum Pump -V192-. If there is a malfunction, replace Brake System Vacuum Pump -V192-.

Note

Note

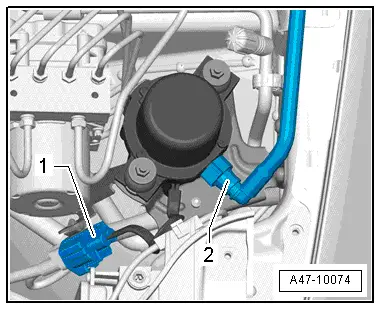

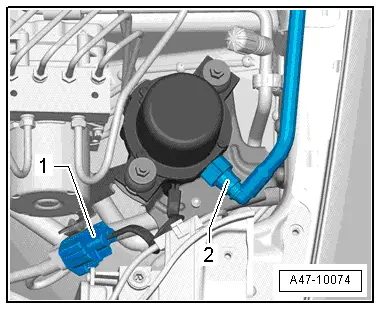

The Brake System Vacuum Pump -V192- is installed in the front of the engine compartment on the left side next to the ABS Hydraulic Unit -N55-.

Removing

- Disconnect the connector -1- and remove it from the clip on the Brake System Vacuum Pump -V192- mount.

- Release the vacuum hose -2- and remove it from the Brake System Vacuum Pump -V192-.

Caution

Caution

Be careful not to damage the vacuum hose. Replace the vacuum hose if damaged.

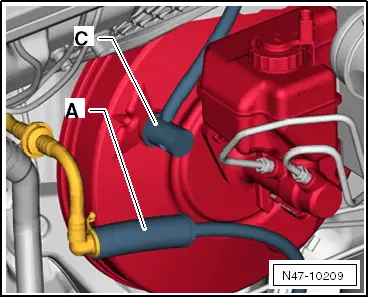

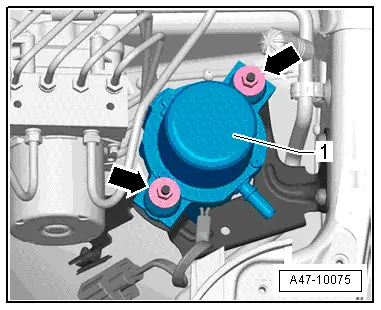

- Remove the nuts -arrows- and then remove the Brake System Vacuum Pump -V192--1- upward.

Installing

- Insert the Brake System Vacuum Pump -V192--1- into the bracket.

Note

Note

Make sure the vacuum pump fits correctly in the bracket. The vacuum connection faces the direction of travel.

- Tighten the Brake System Vacuum Pump -V192- and the nuts -arrow- on the mount.

- Slide the vacuum hose -2- onto the vacuum connection far enough so that it audibly engages.

Caution

Caution

Be careful not to damage the vacuum hose. Replace the vacuum hose if damaged.

- Insert the connector -1- into the clip on the Brake System Vacuum Pump - V192- mount.