Audi Q5: Overview - Wheel Bearing

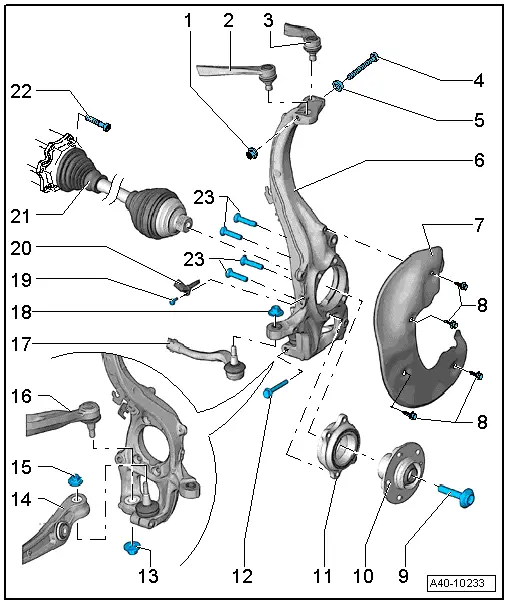

1 - Nut

- 40 Nm

- Always replace if removed

2 - Upper Front Control Arm

3 - Upper Rear Control Arm

4 - Bolt

- Always replace if removed

5 - Washer

6 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing".

- There are different versions. For allocation. Refer to the Parts Catalog.

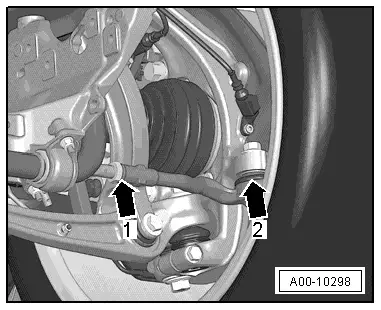

- Distinguishing characteristic.

WARNING

WARNING

When exchanging the wheel bearing housing, make sure the length of the thread on the tie rod end is sufficient (there must be approximately 5 mm extra thread). If this is not the case, then install a new tie rod end with a longer thread pin. Refer to the Parts Catalog.

7 - Brake Shield

8 - Bolt

- 10 Nm

9 - Bolt

- 200 Nm +180º

- Replace after each removal. Refer to → Chapter "Driveshaft General Information".

- Before installing, clean the threads in the CV joint with a tap.

10 - Wheel Hub

- Removing and installing. Refer to → Chapter "Wheel Bearing Unit, Servicing".

11 - Wheel Bearing

- Removing and installing. Refer to → Chapter "Wheel Bearing Unit, Servicing".

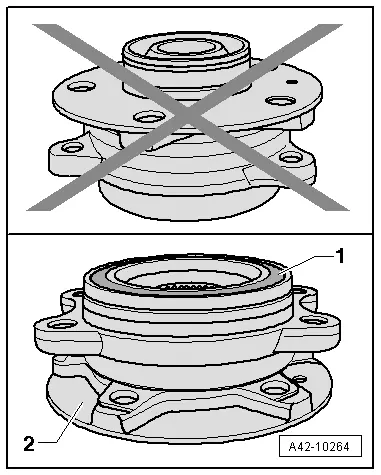

Caution

Caution

Avoid contaminating with dirt and damaging the seal when setting down/storing. Refer to → Fig. "Avoid contaminating with dirt and damaging the seal when setting down/storing.".

12 - Bolt

- 40 Nm

- Always replace if removed

13 - Nut

- Always replace if removed

- There are different versions. For allocation. Refer to the Parts Catalog.

- There are different versions and tightening specifications.

- After loosening threaded connection of guide control arm to wheel bearing housing, adhesive residue must be removed on thread of linkage stub.

14 - Control Arm

15 - Nut

- Always replace if removed

- There are different versions. For allocation. Refer to the Parts Catalog.

- There are different versions and tightening specifications.

- After loosening threaded connection on the ball joint to the wheel bearing housing, adhesive residue must be removed on thread of linkage stub.

16 - Guide Link

17 - Tie Rod End

- There are different versions. For allocation. Refer to the Parts Catalog.

18 - Nut

- There are different versions. For allocation. Refer to the Parts Catalog.

- Pay attention to the different nut versions and to the tightening specifications.

- Always replace if removed

19 - Bolt

- 9 Nm

20 - Speed Sensor

21 - Drive Axle

22 - Bolt

- 70 Nm

- Always replace if removed

23 - Cap Screws

- 80 Nm +90º

- Always replace if removed

Avoid contaminating with dirt and damaging the seal when setting down/storing.

- The wheel bearing -1- must always face up.

- Always set the wheel bearing unit down on the wheel hub -2-.

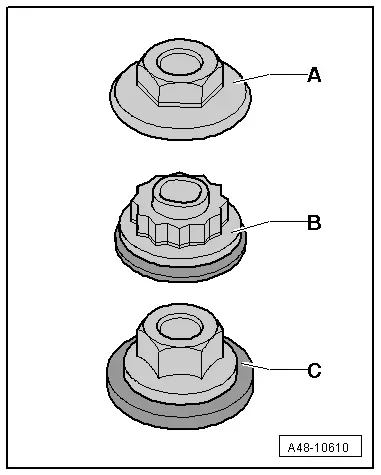

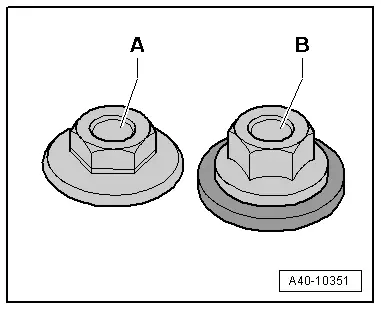

Nut versions for the tie rod ball joint bracket

- Hex collar nut -A-

Tightening specification: 20 Nm 90º.

- Twelve-point combination nut -B-

Tightening specification: 100 Nm

- Hex combi nut -C-

Tightening specifications: 110 Nm

Nut versions for the control arm and guide link bracket

- Hex - collar nut -A- M12 wrench 21 mm

Tightening specification: 145 Nm

- Hex - combination nut -B- M12 18 mm

Tightening specifications: 110 Nm

- Hex - combination nut -B- M12 21 mm

Tightening specification: 120 Nm

- Hex - combination nut -B- M14 21 mm

Tightening specification: 140 Nm

Wheel bearing housing with different steering arm thickness

- The wheel bearing housing differs in the thickness of the steering arm -2-.