Audi Q5: Hydraulic Control Unit, Disassembling and Assembling

Hydraulic Control Unit, Disassembling and Assembling, 0BE, 0BF

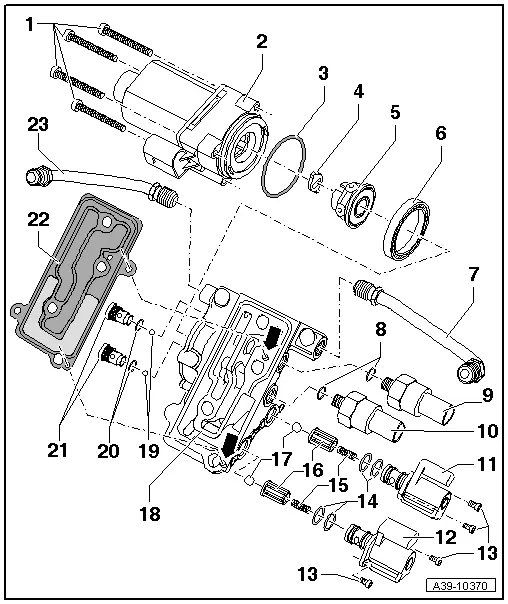

1 - Bolt

- 5 Nm

2 - All Wheel Drive Pump -V415-

- Removing and installing. Refer to → Chapter "All Wheel Drive Pump -V415-, Removing and Installing".

3 - O-Ring

- Always replace.

4 - Adapter

Note

Note

- The adapter could fall out when removing the All Wheel Drive Pump -V415-.

- Insert the adapter into the recesses in the hydraulic pump before installing the All Wheel Drive Pump -V415-.

5 - Hydraulic Pump

- Consists of a guide ring, the housing and six pistons

- Assembling. Refer to → Fig. "Assembling the Hydraulic Pump"

6 - Ball Bearing

- Can be installed and removed by hand

7 - Left Line

- Tighten the nuts to 30 Nm.

- Is installed between the hydraulic control unit and the left chamber

- Tighten both nuts hand-tight when installing

8 - O-Ring

- Always replace.

9 - Oil Pressure/Temperature Sensor -G437-

- 10 Nm

- Brown connector

- Removing and installing. Refer to → Chapter "Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing".

10 - Oil Pressure/Temperature Sensor 2 -G640-

- 10 Nm

- Black connector

- Removing and installing. Refer to → Chapter "Oil Pressure/Temperature Sensor -G437- or Oil Pressure/Temperature Sensor 2 -G640-, Removing and Installing".

11 - All Wheel Drive Clutch Valve 2 -N446-

- Color: brown

- Removing and installing. Refer to → Chapter "All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing".

- Installed position, the connector faces upward toward the Oil Pressure/Temperature Sensor

Caution

Caution

Do not interchange with the All Wheel Drive Clutch Valve -N445-.

12 - All Wheel Drive Clutch Valve -N445-

- Color: black

- Removing and installing. Refer to → Chapter "All Wheel Drive Clutch Valve -N445- or All Wheel Drive Clutch Valve 2 -N446-, Removing and Installing".

- Installed position, the connector faces upward toward the Oil Pressure/Temperature Sensor

Caution

Caution

Do not interchange with the All Wheel Drive Clutch Valve 2 -N446-.

13 - Bolt

- 2.5 Nm

14 - O-Ring

- Always replace.

- Mount onto the Clutch Valve

15 - Pressure Spring

- Insert into the guide -item 16-.

16 - Guide

- Installation position, large diameter faced the ball -item 17-.

17 - Ball

- Insert into the guide before installing -item 16-.

18 - Hydraulic Control Unit Housing

- with centering pins -arrows-

- The centering pins lock the hydraulic control unit and seal to the final drive housing.

19 - Ball

- Install in the hole in the shuttle valve before installing -item 21-.

20 - O-Ring

- Always replace.

21 - Shuttle Valve

- 8 Nm

- Removing and installing. Refer to → Fig. "Removing and Installing the Shuttle Valves".

22 - Seal

- With strainer

- Install on the centering pins in the hydraulic control unit housing

23 - Right Line

- Tighten the nuts to 30 Nm.

- Is installed between the hydraulic control unit and the right chamber

- Tighten both nuts hand-tight when installing

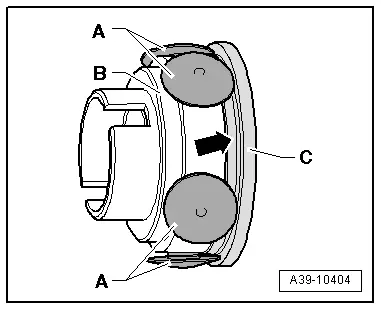

Assembling the Hydraulic Pump

- Install the six pistons -A- in the housing -B-.

- Install the guiding ring -C- so that the piston touches the collar -arrow-.

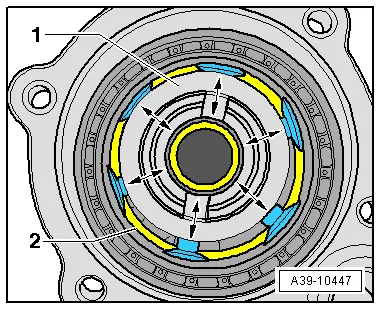

- Insert the hydraulic pump -1- with the guide ring -2- in the in the hydraulic control unit housing.

Function Test:

- Turn the hydraulic pump -1- several times. While doing so pay attention to the following:

- When turning the hydraulic pump must not become hooked or tilted.

- All pistons must be removed and pressed in.

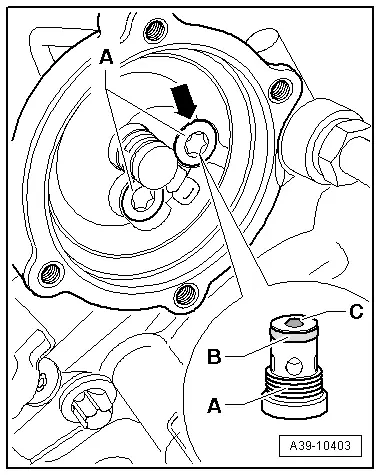

Removing and Installing the Shuttle Valves

Note

Note

Remove the All Wheel Drive Pump -V415-, hydraulic pump and ball bearing -item 6- beforehand.

- Remove the shuttle valves -A-. Always remove the ball -C- as well.

- Insert the ball into the hole in the shuttle valve when installing.

- Install the shuttle valve all the way with a new O-ring -B-.

- The shuttle valve must rest lower than the opposing housing surface -arrow-. If this is not the case, then the remove the valve again and adjust the position of the ball.

- Tighten the shuttle valve to the tightening specification -item 21-.